15

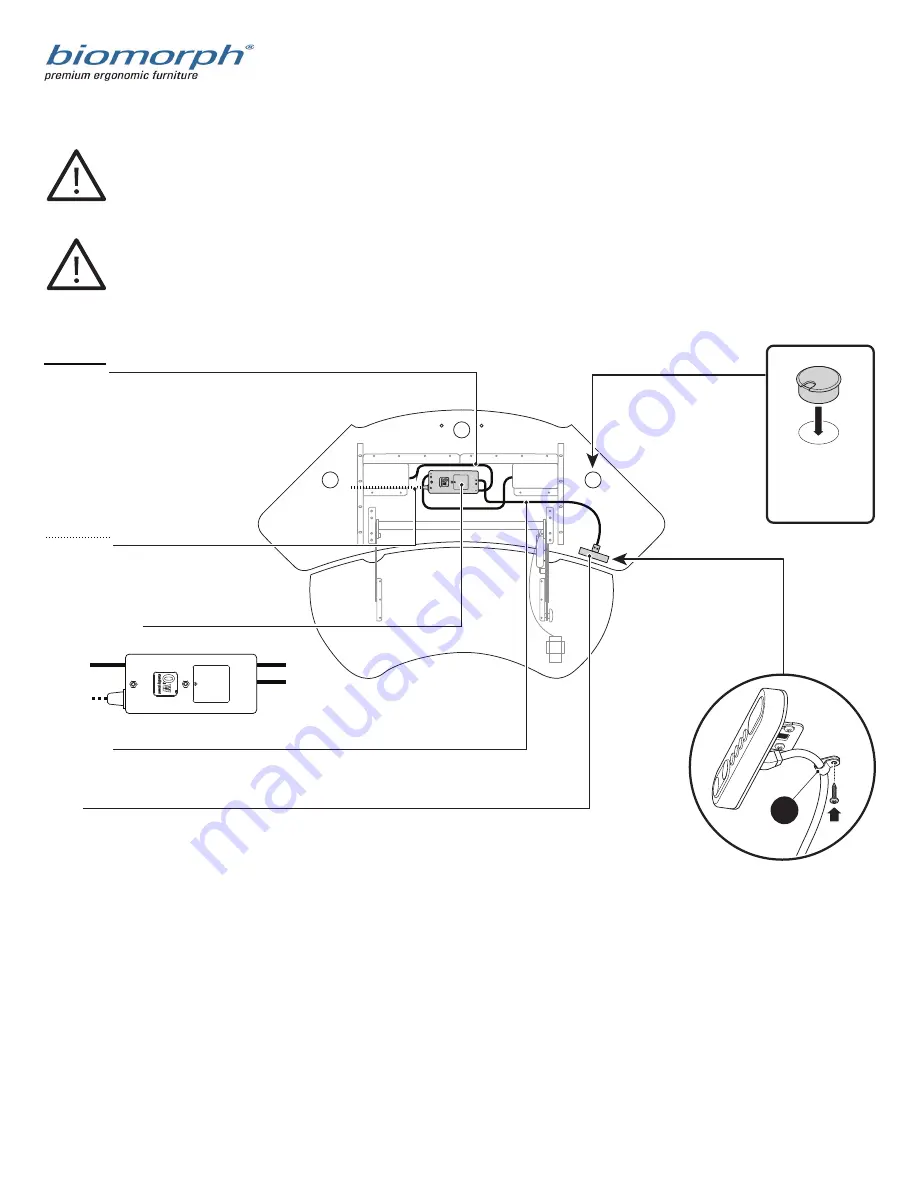

Cable Diagram Corner

IMPORTANT:

All cables must be tacked up and made neat with supplied cable guides. NO cables may hang down ex-

cept those passing through cable chains. Make sure cables have enough slack between surfaces to allow

full height adjustment between surfaces.

IMPORTANT:

Extend desktops to full opposite heights to ensure that cables will travel w/o stress).

GROMMET HOLE

Place grommet into

grommet hole. Route

cable accordingly.

POWER CABLE

Connect power cables to power

strips inside cable cabs.

WIRE CLIP

A wire clip MUST be placed directly

behind switch to prevent cable droop

l

LONG CABLES

Use LONG cables to connect both

legs to ports #1 & #2 in controller box.

CABLE TRACKS

Red FRONT surface

Blue REAR surface

SWITCH

for FRONT surface use long 45˚ angle bracket.

Control switches connect to port A1.

2 PORT CONTROLLER

box for FRONT surface

SWITCH

POWER CABLE

LONG CABLE/

FRONT LEG

LONG CABLE/

FRONT LEG

2

DC

AC

3

4

1

A2

A1

Summary of Contents for Flexo Corner

Page 8: ...8 Top Assembly 5 x 25mm Wood Screw Qty 12 h ...

Page 9: ...9 Top Assembly Corner 5 x 25mm Wood Screw Qty 12 h1 ...

Page 11: ...11 Cable Management k Cable Cab Qty 1 16mm PH Wood Screws Qty 6 k ...

Page 12: ...12 16mm PH Wood Screws Qty 8 Keyboard Mechanism Installation ...

Page 13: ...13 1 1 2 Black Hex Head Nut Bolt Qty 8 Keyboard Mechanism Installation continued ...