EN - 12

5 Functional description

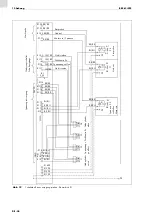

BRS-LCi PLC

5.2 Injection jig

1

The welding torch moves into the cleaning position

2

The control box (HAN 3AQ5: PIN5=24 V) queries the ready signal

3

Once the ready signal is available, the start signal can be set (HAN 3AQ5: PIN5=24V- XS1)

4

Once cleaning is complete, the ready signal is sent from the control box to the robot

5

Injection via 24 V signal on HAN 3AQ5: PIN2

The injection period is specified by the robot.

The anti-spatter fluid volume can be set as required using an adjusting screw

.

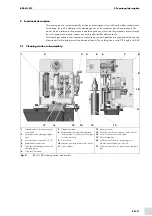

1

Anti-spatter fluid adjusting screw

2

Flow control valve for adjusting the anti-spatter fluid

3

Venturi valve

4

Transmitter disc

5

5/2 directional valve for

injection unit (on/off)

Fig. 5

Reamer injection jig

1

2

3

4

5

WARNING

Risk of crushing

Limbs can be drawn in and crushed by moving parts (reamer, clamping unit).

• Keep your hands away from moving parts.

WARNING

Damage to the eyes

When injecting the anti-spatter fluid, spray mist can form that can damage the eyes.

• Wear safety goggles.

• Only adjust the anti-spatter fluid by opening the solenoid valve Y4.

Summary of Contents for BRS-LCi SPS

Page 4: ...DE 4 1 Identifikation BRS LCi SPS ...

Page 34: ...EN 4 1 Identification BRS LCi PLC ...

Page 64: ...FR 4 1 Identification BRS LCi API ...

Page 94: ...ES 4 1 Identificación BRS LCi PLC ...

Page 123: ...BRS LCi PLC Notas ES 33 Notas ...