RIVA ADVANCE COMBI MANUAL

2

2

9. Venting Cont.

F

Plastic vent requirements

All piping that is used to vent the Riva Advance Combi boiler must conform to the standards

listed below.

It is not permitted to use a cellular core PVC (ASTM F891), cellular core CPVC, or Radel®

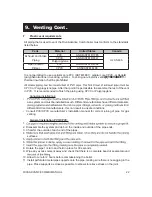

Parts

Material

United States

Canada

Exhaust and Intake

Piping

PVC

ANSI/ASTM D1785

ULC S636

CPVC

ANSI/ASTM DF441

Pipe Cement /

Primer

PVC

ANSI/ASTM D2564

CPVC

ANSI/ASTM F493

(polyphenolsulfone) in venting systems. Covering non-metallic vent

QJQFBOEGJUUJOHT

thermal insulation shall be prohibited.

Polypropylene

CPVC or Polypropylene pipe. After that point it is permissible to assemble the rest of the vent

in PVC.

It is recommended to finish the piping using CPVC or Polypropylene.

Canadian Installations:

•

as a system and must be installed as such. Different manufacturers have different materials,

different BH Vent manufacturers, this can result in unsafe conditions.

•

Consult PVC/CPVC manufacturer’s installation manual for correct joining of pipe for gas

venting.

General installation PVC/CPVC:

1.

2. Disassemble the system and de burr the inside and outside of the pipe ends.

3. Chamfer the outside of each end of the pipes.

4.

surfaces.

5.

6.

7.

8. Rotate the pipe 1/4 turn and hold in place for 30 seconds.

9. Wipe any excess cement away and check that there is a complete bead of sealant around

10. Allow to cure for 2 hours before commissioning the boiler.

11. Install perforated metal pipe supports onto the pipe, making sure there is no sagging in the

pipe. Place supports as close as possible to elbows to relieve stress on the joint.