RJW Series of Rolling Jacks

25

P/N 5900093 — Rev. B — October 2020

Moving a Rolling Jack

Tips for moving a Rolling Jack:

•

Never

try to move a Rolling Jack if it has a Vehicle raised on it.

•

The easiest way to move a Rolling Jack is to use its Moving Handle when the Lift is lowered and no

Vehicle is on the Lift.

•

If you know what Vehicle you are going to be raising, move the Jack(s) to where you think the axles

or lifting points will be

before

driving the Vehicle onto the Lift.

•

Before moving a Rolling Jack, make sure the Rollers are sitting correctly on the Utility Rail Lip or in

the Utility Rail Channel, depending on model. Also,

make sure the Adjustment Bolts and

Safety Brackets are installed and working correctly

.

⚠

WARNING

The safest way to move a Rolling Jack is when the Lift is fully lowered and no

Vehicle is on the Rolling Jack or on the Lift. BendPak strongly recommends always

moving your Rolling Jack with the Lift fully lowered.

•

Do not ever stand or work under a Rolling Jack on a raised Lift.

Additional Operating Information

Keep the following in mind when operating your Rolling Jack

:

•

Check the weight of a Vehicle before attempting to lift it. Do not guess. Never exceed the rated

load capacity of the Rolling Jack.

•

Lift Pads must

always

be used; make sure they are correctly positioned under the axle of the

Vehicle you are raising. Do not raise a load without the Lift Pads. Only the Lift Pads should touch

the Vehicle.

•

Visually inspect your Rolling Jack before each use. Do not use it if you find damage or severe wear.

Make sure the Rollers are on or in the Utility Rails.

•

Do not rock the Vehicle while it is raised or remove items that could cause excessive weight shift.

•

Keep the Utility Rail Channels and Lips clean and free from debris.

Hydraulic Power System Warnings

⚠

WARNING

Failure to observe these precautions can result in serious personal injury, including,

in rare cases, death.

•

The Air-Operated Hydraulic Pump must be correctly connected to the Rolling Jack before raising a

Vehicle or applying air pressure.

•

Do not attempt to connect or disconnect hoses while a Vehicle is raised or while the hydraulic

system is under pressure.

•

Guard against dirt getting into the Air-Operated Hydraulic Pump.

•

Keep bare hands away from the Hydraulic Fluid.

•

When dealing with the Hydraulic Fluid, observe the safety instructions of the manufacturer.

•

Use protective equipment (like safety goggles, protective gloves, suitable working clothes, safety

boots, and so on) when dealing with the hydraulic system.

•

If Hydraulic Fluid comes into contact with the eyes, gets into the bloodstream, or is swallowed,

seek immediate medical attention.

Summary of Contents for RJ45LP

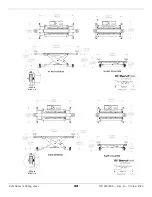

Page 30: ...RJW Series of Rolling Jacks 30 P N 5900093 Rev B October 2020 Labels...

Page 31: ...RJW Series of Rolling Jacks 31 P N 5900093 Rev B October 2020...

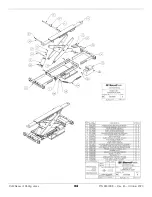

Page 32: ...RJW Series of Rolling Jacks 32 P N 5900093 Rev B October 2020 Parts Sheets...

Page 33: ...RJW Series of Rolling Jacks 33 P N 5900093 Rev B October 2020...

Page 34: ...RJW Series of Rolling Jacks 34 P N 5900093 Rev B October 2020...

Page 35: ...RJW Series of Rolling Jacks 35 P N 5900093 Rev B October 2020...

Page 36: ...RJW Series of Rolling Jacks 36 P N 5900093 Rev B October 2020...

Page 37: ...RJW Series of Rolling Jacks 37 P N 5900093 Rev B October 2020...

Page 38: ...RJW Series of Rolling Jacks 38 P N 5900093 Rev B October 2020...

Page 39: ...RJW Series of Rolling Jacks 39 P N 5900093 Rev B October 2020...

Page 40: ...RJW Series of Rolling Jacks 40 P N 5900093 Rev B October 2020...

Page 41: ...RJW Series of Rolling Jacks 41 P N 5900093 Rev B October 2020...

Page 42: ...RJW Series of Rolling Jacks 42 P N 5900093 Rev B October 2020 Maintenance Log...

Page 44: ...1645 Lemonwood Drive Santa Paula CA 93060 USA 2020 BendPak Inc All rights reserved bendpak com...