RJW Series of Rolling Jacks

21

P/N 5900093 — Rev. B — October 2020

3.

Press and hold the

RELEASE

end to lower the Rolling Jack down onto the nearest Safety Lock.

4.

Release the

RELEASE

end of the pump when the Jack engages on the Safety Lock.

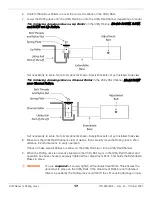

This drawing shows the Jack engaged on a Safety Lock; the Safety Lock is held in place on the

Safety Lock Pin by the weight of the Vehicle on the Rolling Jack.

⚠

WARNING

Only leave your Rolling Jack on a Safety Lock or fully lowered.

5.

To lower the Rolling Jack: press the

PUMP

end of the pedal to get it off the Safety Lock Pin, pull

up on the Safety Handle to move the Safety Lock Pins out of the way, then press and hold the

RELEASE

end of the Pump.

The Rolling Jack begins lowering.

6.

When the Jack is fully lowered, release the

RELEASE

end of the pedal.

Assuming the test went fine, your Rolling Jack is ready for normal operation.

If there were issues, resolve the issues before beginning normal operation. Refer to

Summary of Contents for RJ45LP

Page 30: ...RJW Series of Rolling Jacks 30 P N 5900093 Rev B October 2020 Labels...

Page 31: ...RJW Series of Rolling Jacks 31 P N 5900093 Rev B October 2020...

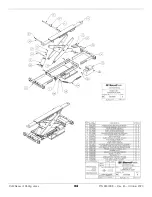

Page 32: ...RJW Series of Rolling Jacks 32 P N 5900093 Rev B October 2020 Parts Sheets...

Page 33: ...RJW Series of Rolling Jacks 33 P N 5900093 Rev B October 2020...

Page 34: ...RJW Series of Rolling Jacks 34 P N 5900093 Rev B October 2020...

Page 35: ...RJW Series of Rolling Jacks 35 P N 5900093 Rev B October 2020...

Page 36: ...RJW Series of Rolling Jacks 36 P N 5900093 Rev B October 2020...

Page 37: ...RJW Series of Rolling Jacks 37 P N 5900093 Rev B October 2020...

Page 38: ...RJW Series of Rolling Jacks 38 P N 5900093 Rev B October 2020...

Page 39: ...RJW Series of Rolling Jacks 39 P N 5900093 Rev B October 2020...

Page 40: ...RJW Series of Rolling Jacks 40 P N 5900093 Rev B October 2020...

Page 41: ...RJW Series of Rolling Jacks 41 P N 5900093 Rev B October 2020...

Page 42: ...RJW Series of Rolling Jacks 42 P N 5900093 Rev B October 2020 Maintenance Log...

Page 44: ...1645 Lemonwood Drive Santa Paula CA 93060 USA 2020 BendPak Inc All rights reserved bendpak com...