2.2 INSTALLATION SITE

Failure to install dryer in the proper ambient conditions will affect the dryer’s ability to condense refrigerant gas.

This can cause higher loads on the compressor, loss of dryer efficiency and performance, overheated condenser

fan motors, electrical component failure and dryer failure due to the following: compressor loss, fan motor failure

and electrical component failure. Failures of this type will affect warranty considerations.

Do not install dryer in an environment of corrosive chemicals, explosive gasses, poisonous gasses, steam heat,

areas of high ambient conditions or extreme dust and dirt.

In case of fire, use an approved fire extinguisher,

w

ater is not an acceptable means in cases of electrical fire.

Minimal installation requirements:

•

Select a clean, dry room, free from dust, and protected from atmospheric disturbances.

•

The supporting plate must be smooth, horizontal and able to hold the weight of the dryer.

•

Minimum ambient temperatures 34°F see the data plate for maximum temperature.

•

Allow at least 16 inches of clearance on each side of the dryer for proper ventilation and to facilitate

maintenance operations.

The dryer doesn't require to be fixed to the supporting surface. Locks will be required for special installations

(on brackets, hanging, etc.).

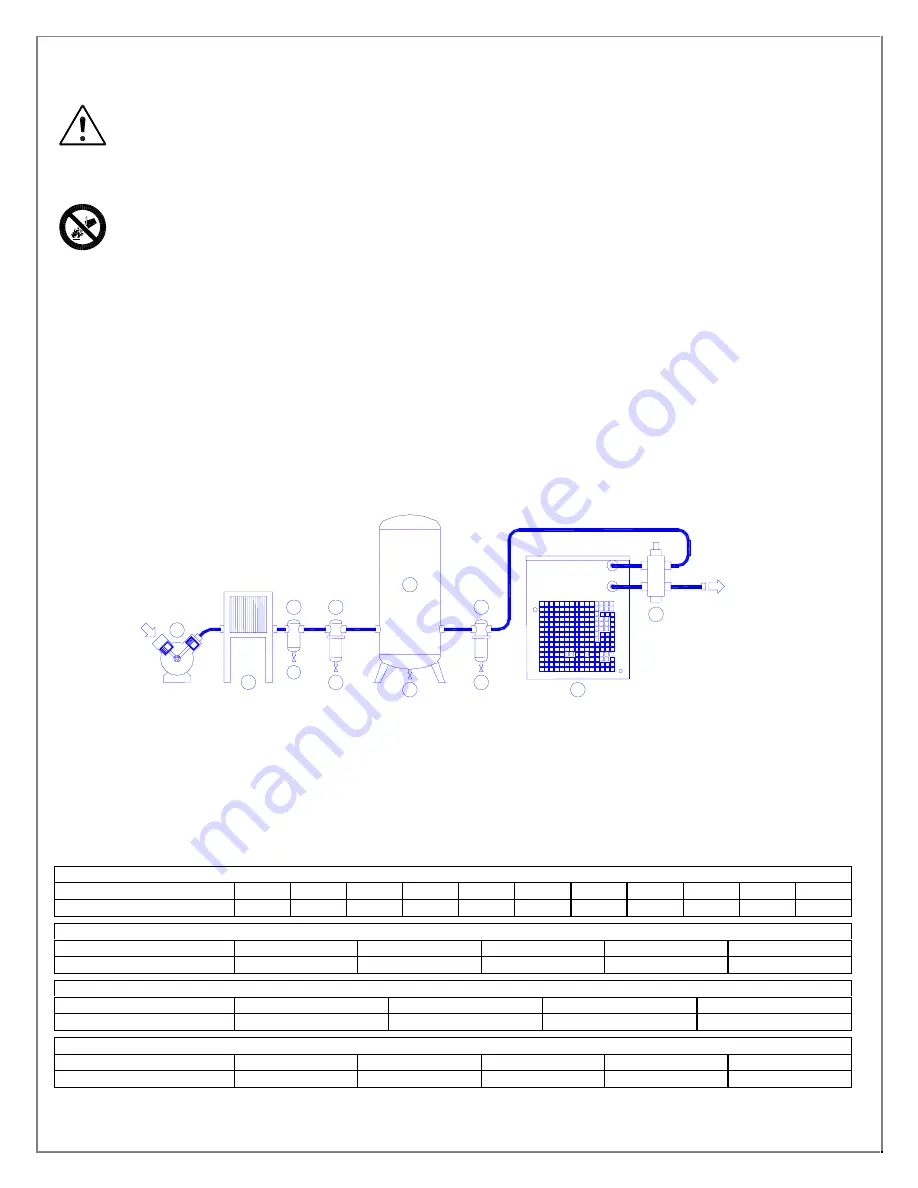

2.3 INSTALLATION LAYOUT

1

Air compressor

6

Final filter

2

Aftercooler

7

Dryer

3

Condensate separator

8

By-pass group (optional)

4

Pre-Filter

9

Condensate drain

5

Compressed air receiver

Correction factor for inlet air pressure changes:

Inlet air pressure

psig

60

70

85

100

115

130

140

155

170

200

232

Factor

0.70

0.85

0.93

1.00

1.06

1.11

1.15

1.18

1.21

1.25

1.28

Correction factor for ambient temperature changes:

Ambient temperature

ºF

80

90

100

110

115

Factor

1.09

1.06

1.00

0.90

0.83

Correction factor for inlet air temperature changes:

Air temperature

ºF

90

100

110

115

Factor

1.15

1.00

0.82

0.75

Correction factor for DewPoint changes:

DewPoint ºF

38

40

44

47

50

Factor

1.00

1.05

1.10

1.15

1.20

2

1

9

9

3

4

8

7

9

9

6

5

OUT

IN