5 / EN

Washing Machine / User’s Manual

2 Installation

Refer to the nearest Authorised Service Agent for installation

of the product. To make the product ready for use, review

the information in the user manual and make sure that the

electricity, tap water supply and water drainage systems are

appropriate before calling the Authorized Service Agent. If

they are not, call a qualified technician and plumber to have

any necessary arrangements carried out.

C

Preparation of the location and electrical, tap water and

waste water installations at the place of installation is

under customer's responsibility.

B

warning

:

Installation and electrical connections of

the product must be carried out by the Authorized

Service Agent. Manufacturer shall not be held liable for

damages that may arise from procedures carried out by

unauthorized persons.

A

warning

:

Prior to installation, visually check if the product

has any defects on it. If so, do not have it installed.

Damaged products cause risks for your safety.

C

Make sure that the water inlet and discharge hoses

as well as the power cable are not folded, pinched or

crushed while pushing the product into its place after

installation or cleaning procedures.

2.1 Appropriate installation location

• Place the machine on a rigid floor. Do not place it on a

long pile rug or similar surfaces.

• Total weight of the washing machine and the dryer -with

full load- when they are placed on top of each other

reaches to approx. 180 kilograms. Place the product

on a solid and flat floor that has sufficient load carrying

capacity!

• Do not place the product on the power cable.

• Do not install the product at places where temperature

may fall below 0ºC.

• Place the product at least 1 cm away from the edges of

other furniture.

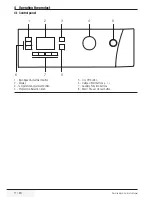

2.2 Removing packaging reinforcement

Tilt the machine backwards to remove the packaging

reinforcement. Remove the packaging reinforcement by

pulling the ribbon.

2.3 Removing the transportation locks

A

warning

:

Do not remove the transportation locks before

taking out the packaging reinforcement.

A

warning

:

Remove the transportation safety bolts before

operating the washing machine! Otherwise, the product

will be damaged.

1. Loosen all the bolts with a suitable spanner until they

rotate freely

(C)

.

2. Remove transportation safety bolts by turning them

gently.

3. Attach the plastic covers supplied in the User Manual bag

into the holes on the rear panel.

(P)

C

Keep the transportation safety bolts in a safe place to

reuse when the washing machine needs to be moved

again in the future.

C

Never move the product without the transportation safety

bolts properly fixed in place!

2.4 Connecting water supply

C

The water supply pressure required to run the product is

between 1 to 10 bars (0.1 – 1 MPa). It is necessary to

have 10 – 80 liters of water flowing from the fully open

tap in one minute to have your machine run smoothly.

Attach a pressure reducing valve if water pressure is

higher.

C

If you are going to use the double water-inlet product

as a single

(cold)

water-inlet unit, you must install the

supplied stopper to the hot water valve before operating

the product. (Applies for the products supplied with a

blind stopper group.)

A

warning

:

Models with a single water inlet should not be

connected to the hot water tap. In such a case the laundry

will get damaged or the product will switch to protection

mode and will not operate.

A

warning

:

Do not use old or used water inlet hoses on the

new product. It may cause stains on your laundry.

1. Connect the special hoses supplied with the product to

the water inlets on the product. Red hose (left) (max. 90

ºC) is for hot water inlet, blue hose (right) (max. 25 ºC) is

for cold water inlet.

A

warning

:

Ensure that the cold and hot water connections

are made correctly when installing the product.

Otherwise, your laundry will come out hot at the end of

the washing process and wear out.

2. Tighten all hose nuts by hand. Never use a tool when

tightening the nuts.