1 697 630 500

2013-03-05

|

Beissbarth GmbH

Initial commissioning | MS 65 OR RAC S80 | 9

en

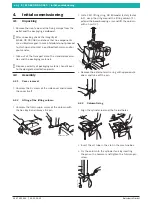

4.

Insert again the pin passing through the cylinder

rod and tie rod holes; put back in place the external

elastic ring.

652012-08_Mi

5.

Connect the pneumatic lock supply pipe on the

pedal box joint.

652012-10_Mi

1

4.2.4

Put in place the vertical rod

1.

Put a hand down on the protection cap (placed on

top of the rod) and press it downwards; with the

other hand remove the steel rod inserted between

the arm and the mounting tool; take off slowly the

hand that was pressing the rod protection cap.

Danger!

The spring could eject violently the rod from

its housing, thus it might be a serious danger

for the operator.

¶

Be careful when carrying out this operati-

on.

2.

Remove the adhesive tape with a cutter.

652012-09_Mi

4.2.5

Mounting of the bead breaking cylinder

1.

Remove the external elastic ring and take off the

hinge rod from its housing in the bead breaking arm.

2.

Disconnect the fixing grain of the fixing bush with

hex key, rotate and unblock the fixing bush to

remove pressure from the spring, remove the fixing

pin and remove the adjusting bush from the bead

breaking cylinder rod .

3.

Insert the bead breaking arm and centre the joint pin

with the cylinder rod, ensuring that the flat part of

the joint pin is facing the outside.

4.

Insert the hinge-pin and put back in place the exter-

nal elastic ring.

5.

Place the buffer spring on the provided tab

6.

Remount the adjusting bush.

Danger!

Wrong mounting of the bead breaking cylin-

der compromises machine functioning and

can be a serious danger for the operator.

¶

During machine installation be sure that

the nut is correctly screwed in the bead

breaking cylinder rod (at least 10 mm).

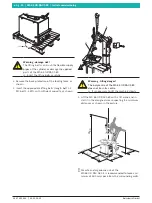

4.2.6

Machine positioning

1.

Put back in place the side door.

2.

Loosen the two screws that fix MS 65 OR RAC S80

to the pallet.