1 697 630 500

2013-03-05

|

Beissbarth GmbH

Operating instructions | MS 65 OR RAC S80 | 15

en

10.

With the provided bead breaking lever lift the

edge of the tire and put lay it on the mounting tool

tab (1).

11.

Press the rotation pedal to rotate clockwise

the locking plate, until complete ejection of the bead

from the rim.

652012-16_Mi

1

i

In case of tires with tube, press the tilting column

pedal to tilt the column and extract the tube.

12.

Repeat the same operations to make the se-

cond bead come out.

13.

Press the tilting column pedal to tilt the co-

lumn and remove the tire.

5.3

Tire mounting

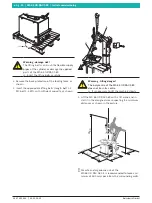

Danger of car accidents caused by damaged

rims or tires!

In case of tire or rim damage during moun-

ting dangerous or even lethal situations may

occur during driving.

¶

The operator has to be specifically trained.

¶

Do not exert excessive forces on the tire or

the rim, adjust the slow rotation speed.

¶

Use a sufficient quantity of mounting

paste.

¶

In case of anomalies, e.g. suspicious noi-

ses, stop mounting immediately.

¶

For mounting of critical rim/tire combina-

tions, read the Wdk publications available

in German and English!(www.wdk.de:

mounting/demounting instructions – crite-

ria catalogue).

5.3.1

Mounting preparations

Warning – damage risk for RFT or UHP tires!

Cracks in case of operation on cold tire. Tire

explosion in case of high speed.

¶

Inner temperature of the tire must be at

least 15 °C.

¶

Read the Wdk publications available in Ger-

man and English! (www.wdk.de: mounting/

demounting instructions – tire overheating)

¶

Before mounting put the tire in a temperate

room.

14.

Lubricate with mounting paste the inside of the

rim in correspondence of the edge and of the shoul-

der of the rim and of the semi drop centre.

15.

Lubricate the two tire beads with mounting

paste.

16.

Lean the tire oblique on the rim.

5.3.2

Mounting

Warning – hand injury danger!

During locking plate rotation there is a risk of

crush injuries.

¶

Do not insert the fingers between the tire

and the rim.

i

In case of remarkable width rims, lift the 2 position

column by means of the dedicated switch.