RD-EK32 Series User Development manual

4

1.3.3 Operation

Self test

:

Step 1:

The power of the printer is turned off.

Step 2:

Press the indicator button

Step 3:

Energize

the printer for about 2 seconds and the printer will start the self-test.

1

、

Paper loading

:

(

1

)

Open paper storage cover

(

2

)

Put paper roll into the Storage, face smooth side up, show around 2cm paper end.

(

3

)

Close the cover to press the paper end, paper loading is over

2

、

Paper feeding

:

Under power up status, press the button is paper feeding.

Note: When label paper is used, the self test must be done in advance for the printer Identify the label seam,

After the self test is done, press the button, if the paper roll automatically move to next label, It means the

identification is succeed, power off then power on ,the data sheet printing operation go on.

二、

Communication interface

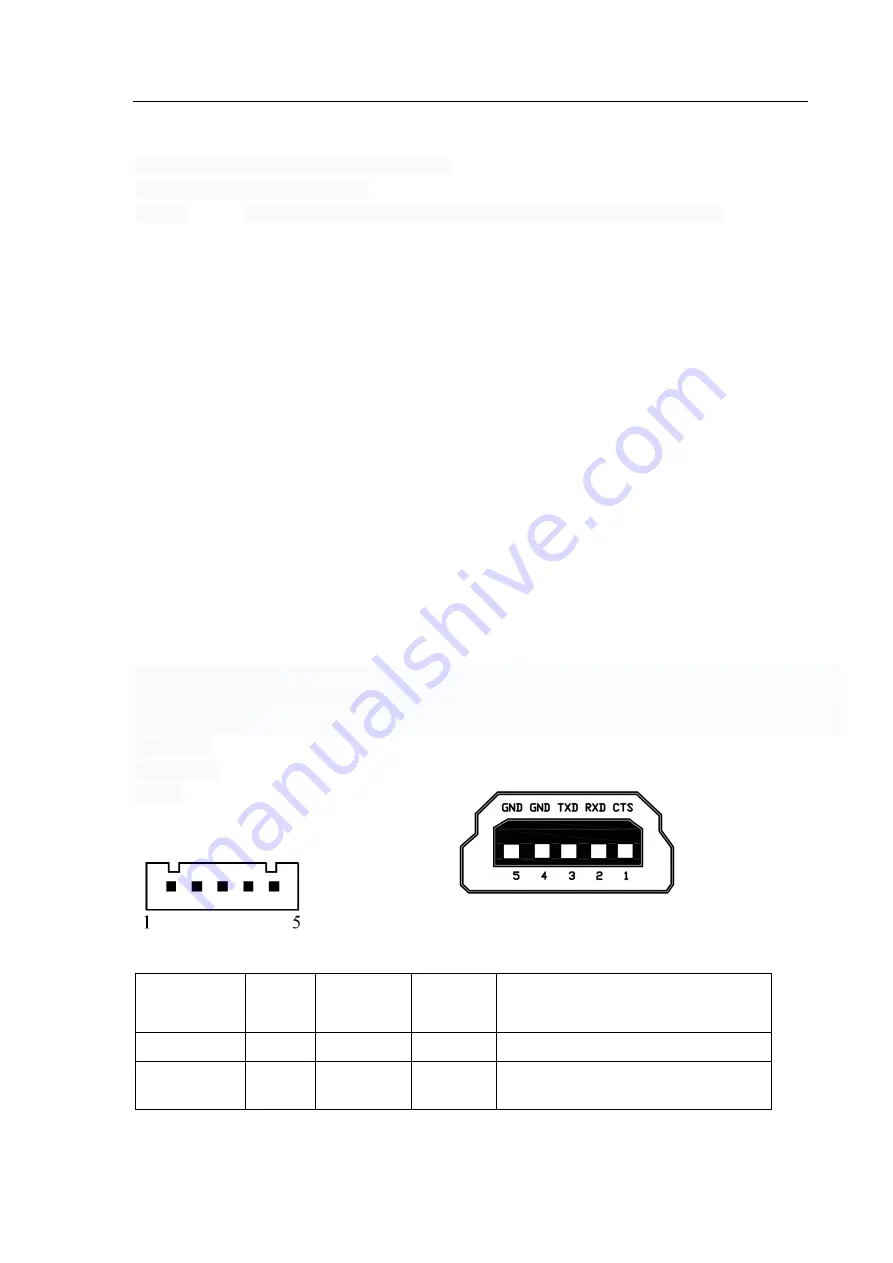

2.1 Serial interface

EK Serial interface adopts 5p white pin seat, Pin space is 2.54mm.

It adopts double serial ports. The side besides power connector is RS232,Other side is TTL port.

2.1.1 Pin definition

Data transfer: Serial

Synchronization way: Asynchronous

Handshake way

:

CTS/RTS

Baud Rate

:

9600

(

Parameter can be set up by button or command

)

Data Length

:

8Bit

Parity

:

None

停止位

stop bits

:

1

;

Interface

:

Side 5pins

5 Core

serial port

Signal

Signal

source

Direction

details

1

-

-

-

Null

2

TXD

Printer

Output

Control board receive data from

mainframe

Pin definition