Mounting and wiring

ELX2002 and ELX2008

26

Version: 2.0.0

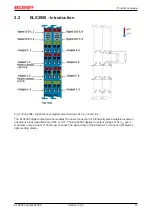

High Density Terminals (HD Terminals) with 16 terminal points

The conductors of the HD Terminals are connected without tools for single-wire conductors using the direct

plug-in technique, i.e. after stripping the wire is simply plugged into the terminal point. The cables are

released, as usual, using the contact release with the aid of a screwdriver. See the following table for the

suitable wire size width.

Terminal housing

High Density Housing

Wire size width (single core wires)

0.08 ... 1.5 mm

2

Wire size width (fine-wire conductors)

0.25 ... 1.5 mm

2

Wire size width (conductors with a wire end sleeve)

0.14 ... 0.75 mm

2

Wire size width (ultrasonically “bonded" conductors)

only 1.5 mm

2

Wire stripping length

8 ... 9 mm

3.6.3

Proper line connection

Always connect only one wire per terminal point.

When using fine-wire conductors it is recommended to connect them with wire end sleeves in order to

establish a safe, conductive connection.

In addition, make sure that the pin assignment is correct to prevent damage to the ELX terminals and the

connected devices.

3.6.4

Shielding and potential separation

Shielding

Encoder, analog sensors and actors should always be connected with shielded, twisted paired

wires.

CAUTION

Observe installation requirements in areas of potentially explosive atmospheres!

During installation, observe the requirements for cables, shielding and earth potential equalization in areas

of potentially explosive atmospheres according to IEC 60079-11, IEC 60079-14 and IEC 60079-25.

WARNING

Ensure potential separation of the 24 V Ex busbar!

In any case, make sure that the galvanic isolation made by the ELX9560 between the 24 V Ex busbar

(power co24 V Ex and 0 V Ex) and other system potentials (if applicable also functional or protec-

tive earths) is not removed.

Summary of Contents for ELX2002

Page 2: ......

Page 4: ...Table of contents ELX2002 and ELX2008 4 Version 2 0 0...