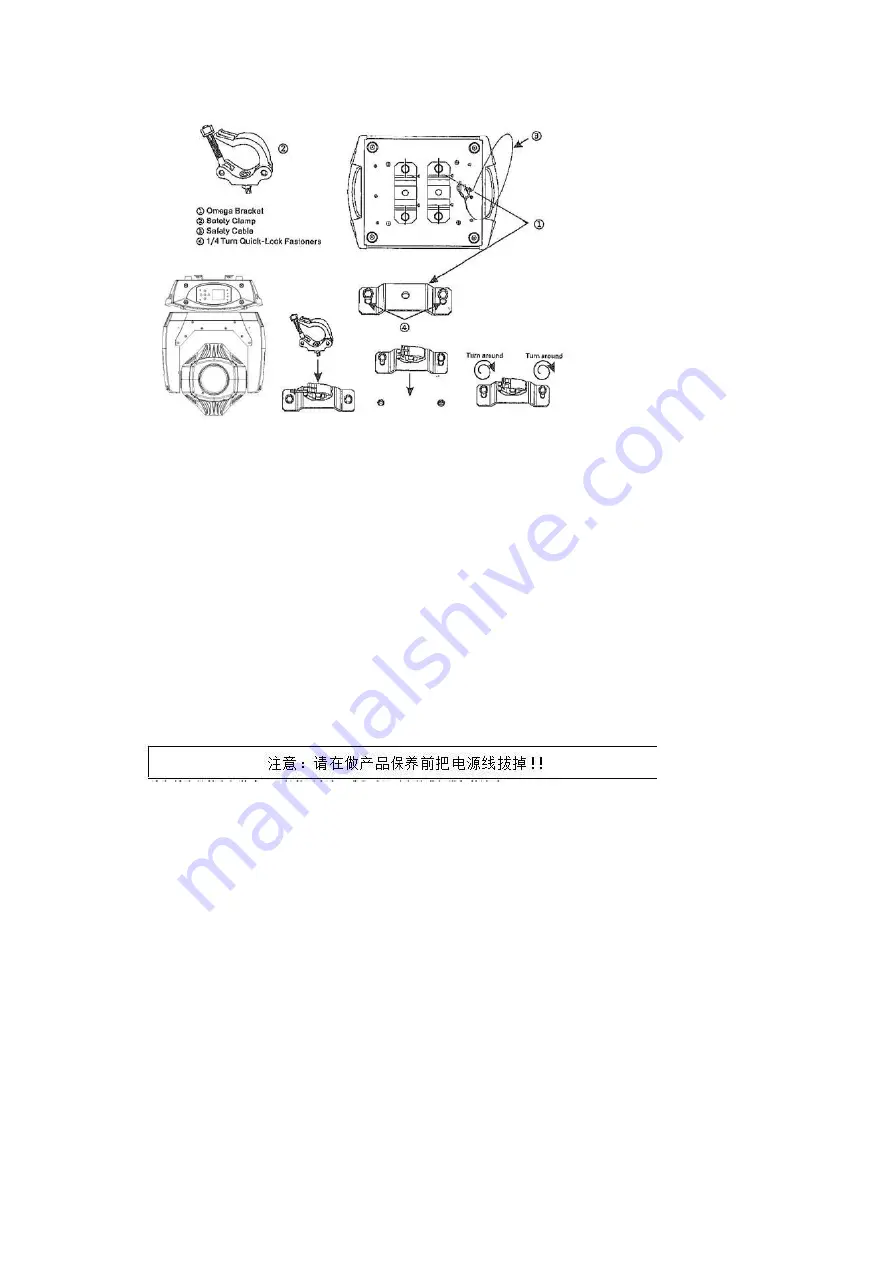

9. product maintenance and cleaning

When testing this product, please pay attention to the following points:

1. the screws and components of all the installation products must be

tightly connected and not rusted.

2. shell, lens, fixings and installation locations (e.g. ceiling, hangers,

trusses, etc.) can not be deformed.

3. mechanical moving parts can not be worn and can not be rotated

unevenly.

4. the power cord must not be damaged, broken or damaged.

The installation and use of products must be carried out by trained

professional and technical personnel.

In order to keep the product in good condition and prolong its service life, we

suggest cleaning the products regularly.

1. clean the external lens and internal lens of the product every week to prevent

the light output from weakening due to the lens dust.

2. clean the fan every week.

3. every three months by the professional electrical engineer to carry out a

detailed circuit inspection of the product to ensure that the circuit contact

is good to prevent the aging of the circuit contacts due to overheating.

We suggest that products should be cleaned regularly. Please be

careful not to use damp or linen. Do not use alcohol or solvents

for cleaning.

This product is not equipped with replacement parts. Please refer