hydroheat.com.au

20

910.026.1 - EN (AUS)

ISTRUCTIONS PERTAINING TO THE INSTALLER

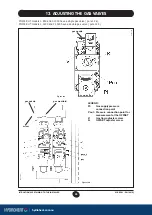

The pumps of the heating system (P1 and P2) have to be connected to boiler terminal block following the wir-

ing of gure 9, a relay must be wired between the boiler control circuit board and the pumps.

12.2 CONNECTING THE PUMPS

Figure 9

Terminal board

Terminal board

Terminal board

Cover

Cover

0902_1202 / CT_0676

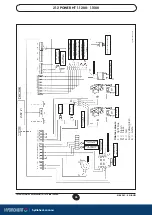

Turn the control box downward to access terminal blocks M1 and M2 used for the electrical connections by

removing the two protective covers (see gure 8).

Terminals 1-2

: connections for the optional SIEMENS QAA73 temperature regulator. These connections do

not have any speci c polarity.

Remove the bridge between terminals 1-2 “TA” on terminal

block

M1.

Read the instructions provided with the temperature regulator to ensure correct installation and programming.

Terminals 3-4

: room temperature thermostat “TA”. Thermostats with integral accelerator resistor must not be

used. Check that there is no voltage across the ends of the two thermostat connection wires.

Terminals 5-6

: oor temperature thermostat connection “TP” (commercially available device). Check that

there is no voltage across the ends of the two thermostat connection wires.

Terminals 7-8

: connections for the optional SIEMENS QAC34 outdoor temperature sensor. Read the instruc-

tions provided with the outdoor temperature sensor to ensure correct installation.

Terminals 9-10

: connections for the optional domestic hot water priority sensor, for connecting single system

boilers to external DHW boilers.

Terminals a-b (230V AC; 50 Hz; 0,5 A max; cos

ϕ

> 0,8)

: electricity supply for boiler pump.

(Feeding relay coil).

12.3 DESCRIPTION OF THE ELECTRICAL CONNECTIONS TO THE BOILER