33

7217395.01

- en

INSTRUCTIONS PERTAINING TO THE USER

IMPORTANT

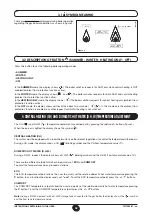

: Regularly check that the pressure displayed by the pressostat (figure 3) is 0.7 to 1.5 bar, with boiler not

operating. In case of overpressure, open the boiler drain valve (Figure 3).

In case the pressure is lower open the boiler filling tap (Figure 3).

We recommend you open the tap very slowly in order to let off the air.

During this operation, the gas boiler must be in “OFF” mode (press the button - See section 3.2).

NOTE: In case pressure drops occur frequently have the boiler checked by a Qualified Service Engineer.

5. FILLING THE BOILER

The electric supply to the boiler must be removed in order to switch it

OFF

.

With the gas boiler in “

OFF

” mode (section 3.2), the display reads out “

OFF

” but the main board is still supplied.

6. TURNING OFF THE BOILER

7. GAS CHANGE

These boilers set for natural gas can be converted to work with

LPG

.

Any gas change must be effected by a Qualified Service Engineer.

We recommend you avoid draining the whole system as water replacements engender purposeless and harmful limestone

deposits inside the boiler and on the heating elements. In case the boiler is not operated during wintertime and is therefore

exposed to danger of frost we suggest you add some specific-purpose anti-freeze to the water contained in the system

(e.g.: propylene glycole coupled with corrosion and scaling inhibitors).

The electronic management of boilers includes a “frost protection” function in the central heating system which operates

the burner to reach a heating flow temperature of 30° C when the system heating flow temperature drops below 5°C.

The frost protection function is enabled if:

* electrical supply to the boiler is on;

* the gas service cock is open;

* the system pressure is as required;

* the boiler is not blocked.

8. PROLONGED STANDSTILL OF THE SYSTEM. FROST PROTECTION

Figure 3

Filling tap

Drain point

Manometer

0901_0802 / CG_1791