This is a publication by Conrad Electronic SE, Klaus-Conrad-Str. 1, D-92240 Hirschau (www.conrad.com).

All rights including translation reserved. Reproduction by any method, e.g. photocopy, microfilming, or the capture in

electronic data processing systems require the prior written approval by the editor. Reprinting, also in part, is prohibited.

This publication represent the technical status at the time of printing.

© Copyright 2018 by Conrad Electronic SE.

1664602_V1_0818_02_VTP_m_en

• Make sure that all accessories and the tool holder of the device fit each other.

• Use only tools and accessories provided by the manufacturer or ones of identical

construction for this device.

• The permitted rotational speed for a replacement tool must be at least as high as

the highest rotational speed of the device.

• Tools or external accessories must fit together; otherwise, it can result in imbal-

anced running, vibrations, etc.

• Never set the power tool down before the tool insert has come to a complete stop.

The turning tool insert can come into contact with the work surface, which can

cause you to lose control of the power tool.

• Never let the power tool run while you carry it. Your clothing can be caught by

accidental contact with the turning tool insert, and the tool insert can gouge into

your body.

• Hold the device securely while working so that you can keep control over it even

in the case of a recoil. Recoils can easily cause severe injuries. Pay attention

to secure and even steering of the tool while you work so as to avoid recoils as

much as possible.

• Avoid freehand grinding without a hand rest. Make sure you stand or rest your

hand and arm securely.

• Do not use any cracked, deformed, unbalanced or vibrating cutting discs, grinding

wheels or grinding pins.

• Always select the tool suited for a work step. Cutting discs, for example, must not

be used for grinding.

• Before using a tool, you should make sure that it is properly mounted and tight-

ened, the free run has been checked by turning with the hand and a test run has

been undertaken, during which you let the tool run unloaded at a secure place for

approx. one minute at the highest speed.

• When working, wear safety glasses, hearing protection and a dust mask. It may

be advisable to wear an apron and possibly also safety shoes and gloves.

• Do not wear any jewellery while working.

• Secure your hair or loose clothing by suitable means so that these cannot be

caught in rotating parts.

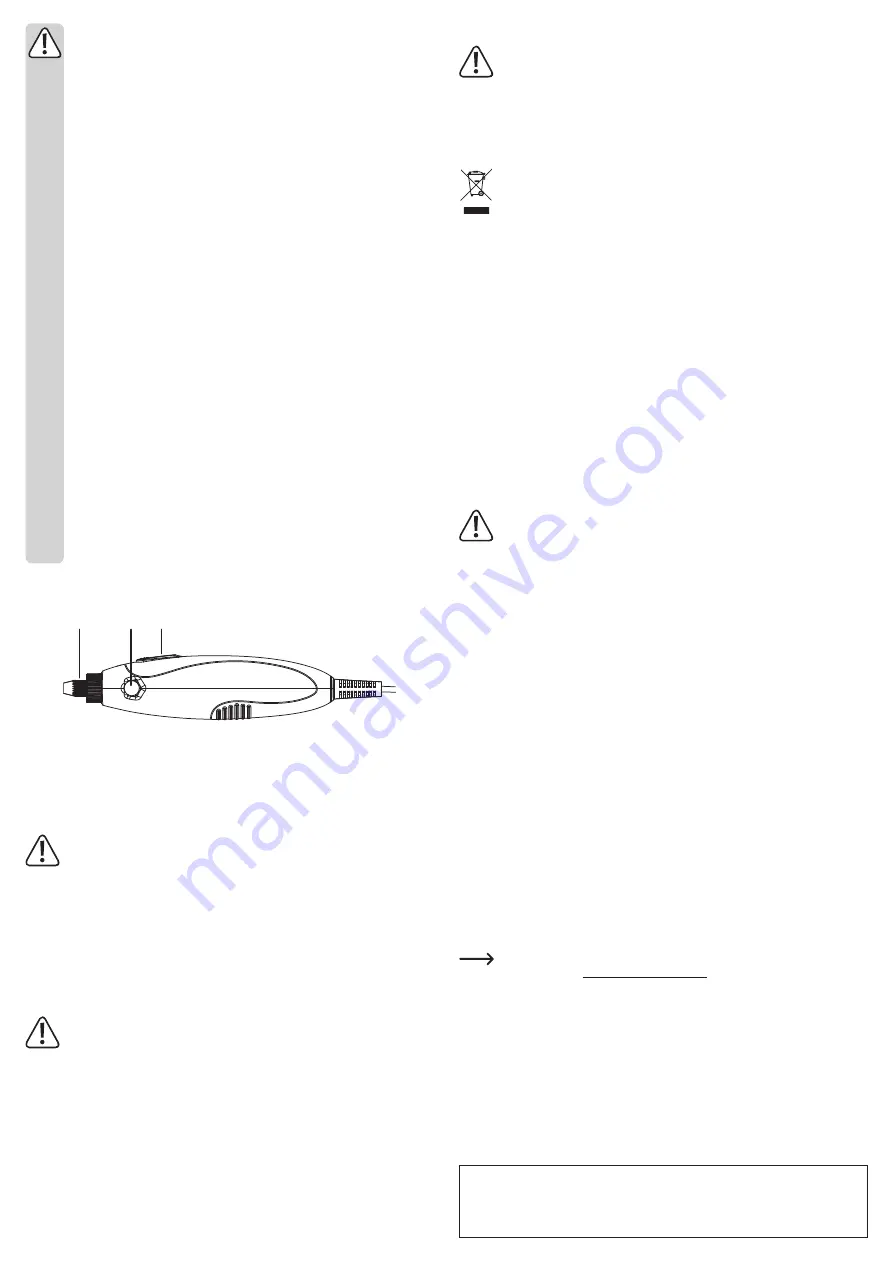

Individual parts and controls

1

2 3

1 Tool holder

2 Locking button

3 ON/OFF switch

Getting started

a) Securing the tool

Before securing or changing the tool insert, disconnect the device from the power

supply (pull the USB plug!).

• Select the tool suited for the work step.

• Mount cutting discs, polishing disks and grinding attachments on the holders they go with

(if necessary).

• Press the locking button (2) on the device to lock the drive shaft.

• Loosen the black lock nut on the tool holder (1).

• Insert the shaft of the selected tool as far as possible into the tool holder (1) and tighten the

previously loosened lock nut well.

b) Connecting the power supply

To power the device, only a mains cable or a power bank with USB output and cor-

responding load capacity (min. 2 A) may be used. A USB interface on a computer

would be overloaded by the increased current consumption of the device. This can

cause damage to your computer.

• Connect the USB plug to the power supply.

c) Processing of the workpiece

• Securely clamp workpieces to be processed, or secure them in a suitable manner against

uncontrolled movements during the processing.

• Press the on/off switch (1) in order to start working.

• Release the on/off switch (1) to turn the device off again.

Maintenance and cleaning

Do not use abrasive cleaning agents, cleaning alcohol or other chemical solutions

since these could damage the housing or even impair operation.

• Before cleaning, the product must be disconnected from the power supply.

• You can use a clean, dry, soft cloth for cleaning. Dust can be easily removed with a soft,

clean brush.

Disposal

Electronic devices are recyclable materials and do not belong in the household

waste. Dispose of an unserviceable product in accordance with the relevant statu-

tory regulations.

Technical data

Rated voltage .......................................5 V/DC (via USB connection)

Power consumption ..............................max. 2 A

Rated idle rotational speed n

0

...............18000 U/min

Tool shaft holder ...................................2.35 mm

Sound pressure level L

PA

......................67.8 dB(A)

Sound power level L

WA

..........................78.8 dB(A)

Standard deviation K ............................3 dB(A)

Vibration (according to EN 60745) .......4.1 m/s²

Uncertainty K ........................................1.5 m/s²

Dimensions ...........................................168 x 29 x 34 mm

Weight ..................................................99 g

Operating and storage conditions .........0 to +40 °C / 20-90% relative humidity (noncondensing)

Attention!

The sound level during work can exceed 80 dB(A). Wear suitable hearing protection.

The vibration level stated in these instructions has been determined according to a

measurement procedure standardised in EN 60745 and can be used for the com-

parison of power tools. It is also suited for a preliminary estimate of the vibration

load.

The stated vibration level represents the main uses of the power tool. However, if

the power tool is employed for other uses, with differing tool inserts or insufficient

maintenance, the vibration level can differ. This can significantly increase the vibra-

tion load for the entire work period.

For a precise evaluation of the vibration load, the times in which the device is

switched off or is indeed running, but not actually in use should also be taken into

account. This can significantly reduce the vibration load for the entire work period.

Determine additional safety measures for protecting the operator against the ef-

fects of vibrations, such as: Maintenance of power tool and tool inserts, keeping the

hands warm, organisation of the work processes.

Declaration of conformity (DOC)

We, Conrad Electronic SE, Klaus-Conrad-Straße 1, D-92240 Hirschau, hereby declare that this

product conforms to the following directives:

2006/42/EG

2014/30/EU

It was manufactured in conformity with the following standards:

EN 60745-1:2009/A11:2010

EN 60745-2-23:2013

EN 55014-1:2006/A2:2011

EN 55014-1:2017

EN 55014-2:2015

The full text of the original EU conformity declaration is available via the following

Internet address: www.conrad.com/downloads

Select the language by clicking a flag symbol and enter the order number of the

product in the search field; then you will be able to download the original EU declara-

tion of conformity in PDF format.