21

V

alue

S

erieS

V-710iJ M

anual

If a jam occurs during operation, follow these steps:

1. Turn the feeder power Off by pushing the circle (

O

) at the

rocker

Power

On/Off rocker switch.

2. Remove jammed product from feeder. While doing so, try to

determine the cause of the jam (see Section 5, “Troubleshoot

-

ing”).

3. Verify whether any adjustments are loose. If so, refer back to

Section 3, “Preparing for Operation”, for proper adjustment

procedures.

4. Turn the feeder power back On by pushing the horizontal line

(

—

) at the

Power

On/Off rocker switch.

Should you not be using the feeder for long periods of time, follow

these steps to ensure safe and secure storage:

1. Turn the feeder power Off by pushing the circle (

O

) at the

rocker

Power

On/Off rocker switch.

2. Disconnect the feeder power cord from the AC power source.

If installed, disconnect external run input from feeder control

panel.

3. Cover the feeder with a cloth or plastic tarp to prevent dust

and debris from accumulating.

Shutdown

Clearing a Jam

Summary of Contents for Streamfeeder Value Series

Page 1: ...Manual Value Series V 710IJ...

Page 24: ...18 Value Series V 710IJ Manual Notes...

Page 28: ...22 Value Series V 710IJ Manual Notes...

Page 36: ...30 Value Series V 710IJ Manual Notes...

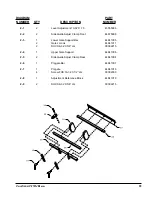

Page 37: ...31 Value Series V 710IJ Manual 7 Mechanical Components...

Page 41: ...35 Value Series V 710IJ Manual...

Page 43: ...37 Value Series V 710IJ Manual...

Page 45: ...39 Value Series V 710IJ Manual...

Page 49: ...43 Value Series V 710IJ Manual...

Page 51: ...45 Value Series V 710IJ Manual...

Page 52: ...46 Value Series V 710IJ Manual 8 Electrical Components...

Page 53: ...47 Value Series V 710IJ Manual...

Page 54: ...48 Value Series V 710IJ Manual...

Page 55: ...49 Value Series V 710IJ Manual...

Page 56: ...50 Value Series V 710IJ Manual Notes...

Page 57: ......

Page 58: ...2009 Thiele Technologies Inc Streamfeeder Printed in the USA...