10

Seal -

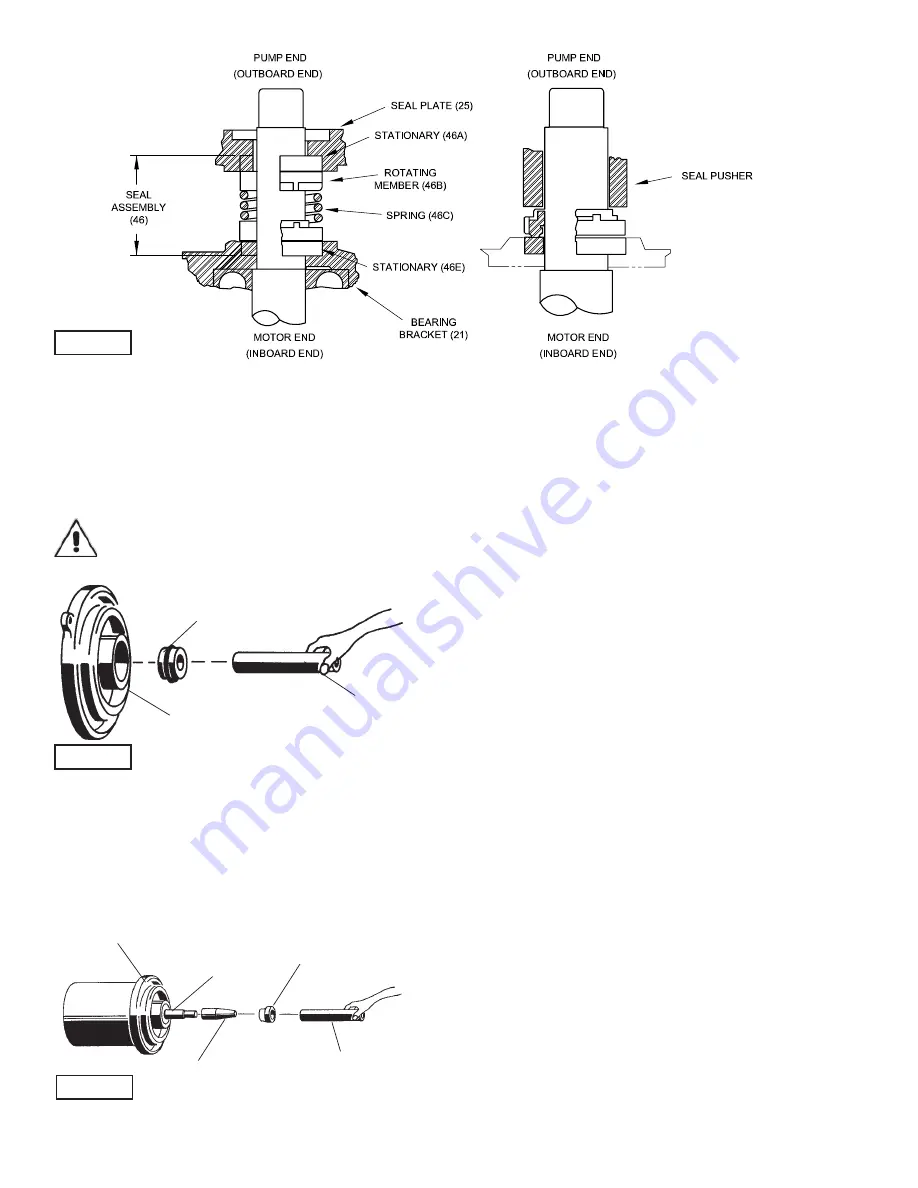

Clean and oil seal cavities in bearing bracket (21)

and seal plate (25). Lightly oil

(DO NOT use grease)

outer

surface of inboard stationary member (46E) and outboard

stationary member (46A). Press inboard stationary member

(46E) fi rmly into bearing bracket (21) and outboard stationary

(46A) into seal plate (25), using a seal pusher (see parts list-

seal tool kit), nothing but the seal pusher is to come in contact

with seal face (See Figures 2 & 3).

Important ! - DO NOT hammer on the seal pusher-

it will damage the seal face.

Make sure the stationary members are in straight and that

the rubber ring is not out of it’s groove. Lightly oil

(DO NOT

use grease)

shaft and inner surface of bellows on rotating

member (46D) See Figure 4. With lapped surface facing

bearing bracket (21), slide rotating member (46D) onto shaft,

using seal pusher, until lapped faces of (46D) and (46E) are

together (See Figure 2). It is extremely important to keep seal

faces clean during assembly. Dirt particles lodged between

these faces will cause the seal to leak.

Make sure driving lugs in retainer are matched in rotating

member. Place spring (46C) over shaft and in place on rotat-

ing member (4E), making sure it is seated in retainer and not

cocked or resting on bellows tail. Re-oil shaft and lightly oil

inner surface of outboard rotating member (46B). With tail

section toward bearing bracket (21), slide rotating member

(46B) onto shaft with seal pusher until retainer engages spring

(46C) and spring is compressed slightly. Make sure spring

(46C) is properly engaged in both retainers. Insert o-ring (42)

onto bearing braket (21). Slide seal plate (25) over shaft onto

bearing bracket (21), being careful not to damage outboard

stationary member (46A) and align holes for socket head cap

screws (39). Thread socket head cap screws (39) into bearing

bracket (21) and tighten. Fill seal chamber with oil as outlined

in paragraph F-1.3. Reassemble impeller and volute per para-

graph F-2.2.

F-4.3) Wiring Connections:

Check power cable (10A) and control cable (10D), on conduit

box (10), for cracks or damage and replace complete conduit

box assembly (10) if required (See Fig. 5). Bring motor wires

through wire opening in top of housing (2),check sleeving (53)

and replace if required, position square ring (11) in conduit

housing (10) and reconnect motor leads to power cable and

moisture and temperature sensor leads to control cable using

connectors (12), (17) and insulators (54) as show in Figure 6.

F-4.4) Conduit Box and Cable Assembly:

Refi ll with cooling oil as outlined in paragraph F-1.3. Position

conduit box (10) and square ring (11) over opening, apply

thread locking compound to cap screws (6) threads and torque

to 16 ft. lb. Remove gland nuts (10B) and (10F), friction rings

(10C) and (10G), and grommets (10D) and (10H) from conduit

box (10) inspect and replace if required (See Figure 5). Insert

one friction ring (10C), grommet (10D), one friction ring (10C)

and gland nut (10B) into conduit box for power cable (10A). For

control cable (10E), insert grommet (10H), friction ring (10G)

and gland nut (10F). Torque gland nuts (10B) and (10F) to 15

ft. lb. to prevent water leakage.

F-5) Base & Elbow Service:

To clean out base elbow (68) remove cap screws, clean-out

plates (64) and o-ring (67) from elbow (68). Inspect o-ring

and replace if damaged. If gasket (58) is damaged or leaking,

remove hex nuts (61) and lockwashers (60) and remove hard-

ware from piping to drop elbow down. To remove pump from

base (59) remove hex nuts (70) and lockwashers (66) and lift

pump from base.

FIGURE 2

FIGURE 4

Stationary Member (46E)

Polished Face Out

Seal Plate (25)

Seal Pusher

FIGURE 3

Rotating Member (46D)

Bullet

Motor & Bearing Bracket

Seal Pusher

Stationary

Summary of Contents for 6DSE-L Series

Page 5: ...5 inches mm...

Page 14: ...14 FIGURE 7 6DSE L Pump Series...

Page 15: ...15 FIGURE 8 6DSE L Pump Series...

Page 22: ...Notes...