AIRFLOW & DEFROST

Cut-In/Cut-Out

Cut-In

Temp (

o

F)

Cut-Out

Temp (

o

F)

Pans

33

29

Top Coil

36

31

AIRFLOW & PRODUCT LOAD

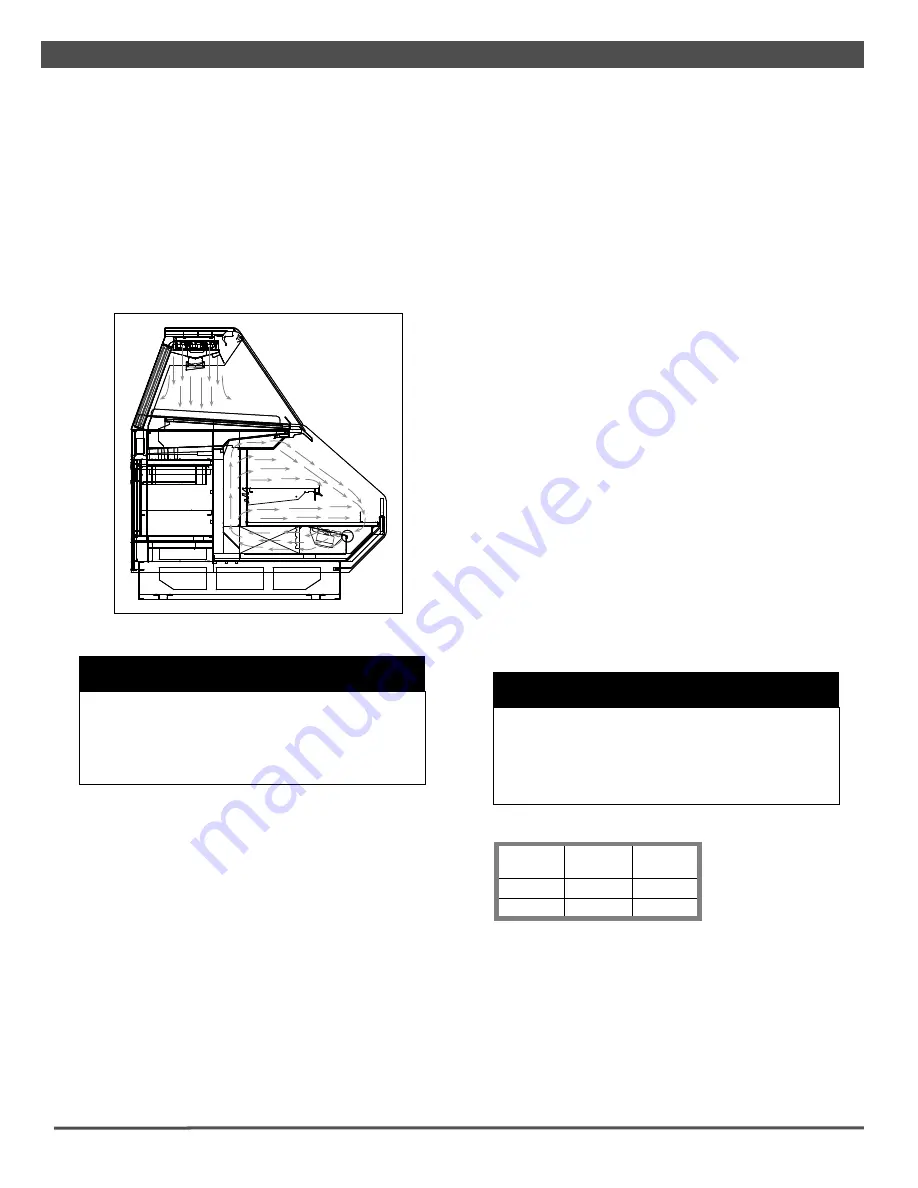

Hillphoenix cases provide maximum product capacity within the

refrigerated air envelope. Please keep products within the ap-

propriate load limit.

It is important that you do not overload the food product display

so that it

impinges on the airfl ow pattern (Fig. 11). Overload-

ing will cause malfunction and the loss of proper temperature

levels, particularly when discharge and return air sections are

covered.

W A R N I N G

Always keep product within the designated air

curtain. Failure to do so may result in case

malfunction and product losing proper tempera-

ture, resulting in sub-standard operation and

increased chances of food contamination.

▲

PTD-RGC cases are available with the defrost and temperature

controls mounted at the case or initiated by the rack controller.

When the controls are mounted at the case, the single time-off

defrost is initiated by the Dixell XR70CX controller mounted in

the slide out control box. During defrost, all valves close and

the pump cycles OFF. When in refrigeration mode, the glycol

fl ow to the top coil, shelves and the Coolgenix pans is inde-

pendently controlled by the Dixell controller. If none of these

components requires fl ow, all solenoids close (including DX

liquid-line valve) and the pump is cycled OFF.

When defrost and temperature are controlled from the rack,

the time-off defrost is controlled by a set of normally open con-

tacts at the rack controller. When in refrigeration mode, the

top coils, shelf and the Coolgenix pans are controlled as three

independent, temperature-controlled cases. Again, if none of

C A U T I O N

If the shelves are removed from the case or other-

wise not utilized, the shelf setpoint (SAA) must be

raised to 90

o

F to prevent the pump from running

when only the shelves are calling for refrigeration.

Failure to do so could result in early pump failure.

▲

these components requires fl ow, all valves close and the pump

cycles OFF.

Whether the controls are managed at the case or by the rack

controller, the case and product temperatures are maintained

by having the top coils, shelves and the Coolgenix deck pans

cycle through their individual DIFFERENTIAL range. If the

Dixell XR70CX Controller is used, the fl ow of the chilled fl uid to

the Coolgenix pans, shelves and top coil circuit is controlled by

comparing the temperature readings of the appropriate tem-

perature sensor against either the CUT-IN or CUT-OUT setpoint

to the DIFFERENTIAL control settings. To determine CUT-OUT

temperature, calculate the CUT-IN minus the DIFFERENTIAL.

To determine CUT-IN temperature, calculate the CUT-OUT plus

the DIFFERENTIAL. For example, the factory setting for pan

CUT-OUT is 29°F with a 4°F DIFFERENTIAL which yields a CUT-

IN setting of 33°F.

The factory settings should be considered a guide and may

need to be adjusted based on store conditions. Because

these cases are often installed in stores near a meat prepara-

tion area where standard ASHRAE conditions may not apply,

different settings may be required for optimal operation.

It is important to consult the guidelines and control setting

shown on page 2 before setting defrost times. Further adjust-

ment may be required depending on store conditions.

If your case is equipped with a Dixell temperature and humidity

controller, see Appendices B1-B4 for operating instructions.

If you need to convert pressure to temperature see Appendix

C1 for the Sporlan Temperature-Pressure Chart.

DEFROST & TEMPERATURE CONTROLS

Cases are equipped with either Hot Gas or Timed-Off defrost at

the owner's option.

The hot gas defrost termination sensor bulb and probe are

attached to the dump line which is in the front, left-hand side

of the case.

Fig. 11 Airflow pattern

16

Summary of Contents for PTD-RGC

Page 2: ...ii ...