Manual 2100-279

Page 7

CAUTION

A dirty air filter(s) reduces system efficiency

and can cause erratic control performance.

These could result in damage to blower motor

or heat exchanger.

6.D

KEEP AIR FILTER(S) CLEAN

As a user, your personal responsibility is to keep air

filter(s) clean.

1. During the first four weeks after your furnace is

installed, inspect your air filter(s) for dirt every

week. Then check the filters monthly and clean as

necessary.

2. If the filter(s) is of a washable type, clean filter(s)

according to the manufacturer’s specifications.

6.E

DO NOT OBSTRUCT DUCT WORK

For proper operation, keep registers and return air

grilles open. Do not cover or block them with rugs,

carpets, drapes or furniture.

6.F

HAVE YOUR FURNACE CHECKED

ANNUALLY

The furnace, vent terminal, and the combustion air

intake hood should be inspected yearly by a

qualified service agency, generally prior to the

heating season. Detailed procedures for this

inspection are contained in the instructions booklet

and should be handled by the qualified service

agency only.

A general inspection of the furnace, the furnace area

and the vent terminal should be conducted on a

regular basis by the owner/occupant. This review

should include:

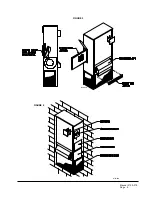

1. Make sure the furnace always has the minimum

clearance as detailed on the furnace rating

plate. Special attention must be given to these

items if any remodeling is done.

2. Make sure the vent terminal is in place and

is physically sound.

SECTION 6 • PROPER MAINTENANCE OF

YOUR FURNACE

You need special abilities, mechanical skills and tools to

maintain your furnace properly. If you are uncertain about

your abilities or if you lack proper skills or tools, do not try

to maintain or repair you furnace yourself. Instead, contact a

qualified installer, service agency or gas supplier.

6.A

IF YOU SMELL GAS OR ANY UNFAMILIAR

SMELL WHILE WORKING ON YOUR

FURNACE:

1. Do not try to light main burners.

2. Do not touch or turn on any electrical switch.

3. Do not use any phone in your building.

4. Immediately call your gas supplier from a

neighbor’s phone. Follow gas supplier’s

instructions.

5. If you cannot reach your gas supplier, call fire

department.

6.B

LUBRICATION REQUIREMENTS

The main blower motor and the induced draft blower

motor are permanently lubricated, and no

maintenance is required.

6.C

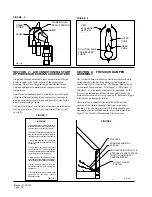

MAKE SURE AIR FILTER(S) IS IN PLACE

Ask your installer, local qualified service technician

or gas supplier to make sure your filter(s) is in place

properly. Become familiar with its location and

procedures for removing, cleaning and replacing it.

Recommended filter sizes are shown below.

MAIN SYSTEM FILTER: 20 X 30 X 1

Fiberglass disposable

FRESH AIR FILTER:

4 x 26 x 1/2

Washable

See Figure 3 for filter locations.

WARNING

Operating furnace without clean air filter(s) can

damage blower motor, heat exchanger or air

conditioning system components. This can

cause system failure which could result in

damage or injury.

WARNING

After cleaning or changing filter(s), filter access

cover(s) must be replaced. Failure to do so

could cause nausea, asphyxiation, or fire

resulting in damage, injury or death.