Manual 2100-279

Page 8

5. Restore the electrical power to the furnace by

turning the switch back on. Adjust the

thermostat to call for heating operation.

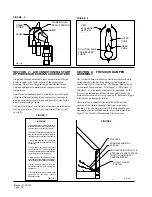

6. Observe both the pilot flame and main burners

flames, and compare to Figures 5 and 6

respectively. The main burners should be mostly

“blue” with possibly a little orange (not yellow)

at the tips of the flames. The flames should be

in the center of the heat exchanger compartments

and impinging on the heat exchanger surfaces.

7. Observe the flames until the blower starts (there

is a normal delay 60 second period until the heat

exchanger warms up). There should be no

change in the size or shape of the flame. If there

is any wavering or blowing of the flame on the

blower start-up, it is an indication of a possible

leak in the heat exchanger. Turn off the gas

valve in the gas line leading to the furnace, and

then the main electrical switch to the furnace

and call your service agency.

8. Replace the burner access door.

WARNING

Leakage of products of combustion into the

living area may result in asphyxiation resulting in

injury or death

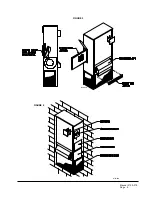

4. Inspect the vent terminal, observing for any

debris from weather, birds, and the like. Clean

if necessary. Also check the small cover

assembly on Induced Draft Blower Door to make

sure it is clear. See Figure 4.

7. Check the entire vent terminal for any blockage.

If any debris is present remove it.

6

.G

THE FOLLOWING PROCEDURE SHOULD

BE FOLLOWED FOR THE PERIODIC

INSPECTION AS CONDUCTED BY THE

OWNER/OCCUPANT.

1. Set the wall thermostat to the OFF position or

lower the set point lever to a temperature will

below the existing room temperature. Shut off

electric power to the furnace. A switch should

be mounted either on the outside of the furnace

or adjacent to the furnace for this purpose.

2. Remove the burner access door. See Figure 4.

3. Use flashlight or trouble light to observe the

burner compartment and burners. There should

be very minimal scaling or sooting in this area.

Some loose debris may have fallen down on to

the floor of the heat exchanger form the tube

passageways, and this may be vacuumed out.

Also observe the sides of the heat exchanger

tubes for “hot spots” due to improper burner

alignment or overfiring and give particular

attention to any area where it looks like there

may be any deterioration from corrosion or

rusting. Observe for any corrosion on the

burners themselves. Should anything appear

questionable, contact your service agency.

3. Reviewing that the return air duct connection(s)

is physically sound, is sealed to the furnace

casing.

4. The physical support of the furnace is sound

without sagging, cracks, gaps, etc. around the

unit so as to provide a seal between the unit

and the structure.

5. Inspect for any obvious signs of deterioration of

the furnace.

6. Periodic examinations of the vent terminal

should also be conducted by the owner on a

regular basis, preferably every monthly but at

least every two months during the heating

season.