Manual 2100-749

Page

61 of 68

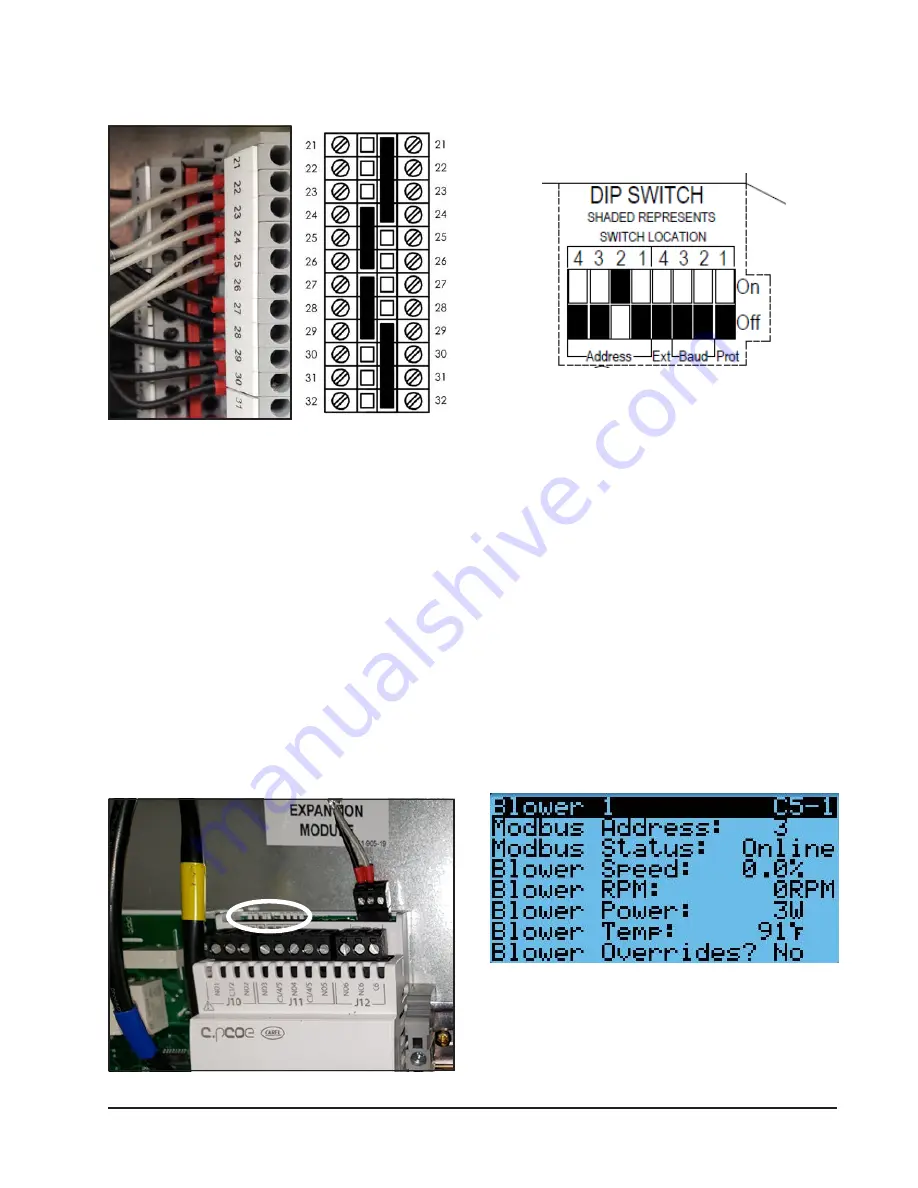

FIGURE 84

Communication Wires in Terminal Block

Verify the terminal block jumpers are placed correctly

as shown above. Terminals 21-26 should all be bonded

together and terminals 27-32 should all be bonded

together.

If problem still persists after verifying correct wiring

and polarity, proceed to the next steps.

NOTE:

The following steps are only for single

communication alarms at specific devices. If

there are multiple devices with communication

failures, the issue is either that polarity of the

wiring is incorrect, the jumpers in the terminal

block are incorrect or the communication port on

the PLC board is damaged.

c.pCOe Communication Failure

1. Locate the addressing DIP switches on the c.pCOe

(see Figure 85).

FIGURE 85

DIP Switch Location

FIGURE 86

Correct DIP Switch Settings

2. Verify the correct DIP switch settings on the

c.pCOe (see Figure 86).

3. If problem persists, verify 24VAC power to c.pCOe,

disconnect communication plug from c.pCOe

and disconnect wires from terminal block. Verify

continuity from end to end and then verify there

are no shorts to ground.

4. To verify the expansion module (C.PCOe) is faulty,

the communication wires should be isolated from

the blower and condenser fan and only connected

to the PLC to establish if communication is

possible.

c.pCOe Tx+/Rx+ wired to PLC FB+

c.pCOe Tx–/Rx– wired to PLC FB–

5. If problem persists after the previous steps, replace

c.pCOe.

Blower Communication Failure

For the following steps, use the TEC-EYE to view the

Modbus status of the blower. This screen is accessible

in the I/O Menu under Fans/Blowers (see Figure 87).

FIGURE 87

TEC-EYE Blower 1 Screen

1. Due to the inability to open the blower motor

terminal access panel while in the unit, swap

the polarity of the communication wires for the

effected blower.

Blower 1: Terminals 26 and 32

Blower 2: Terminals 24 and 30