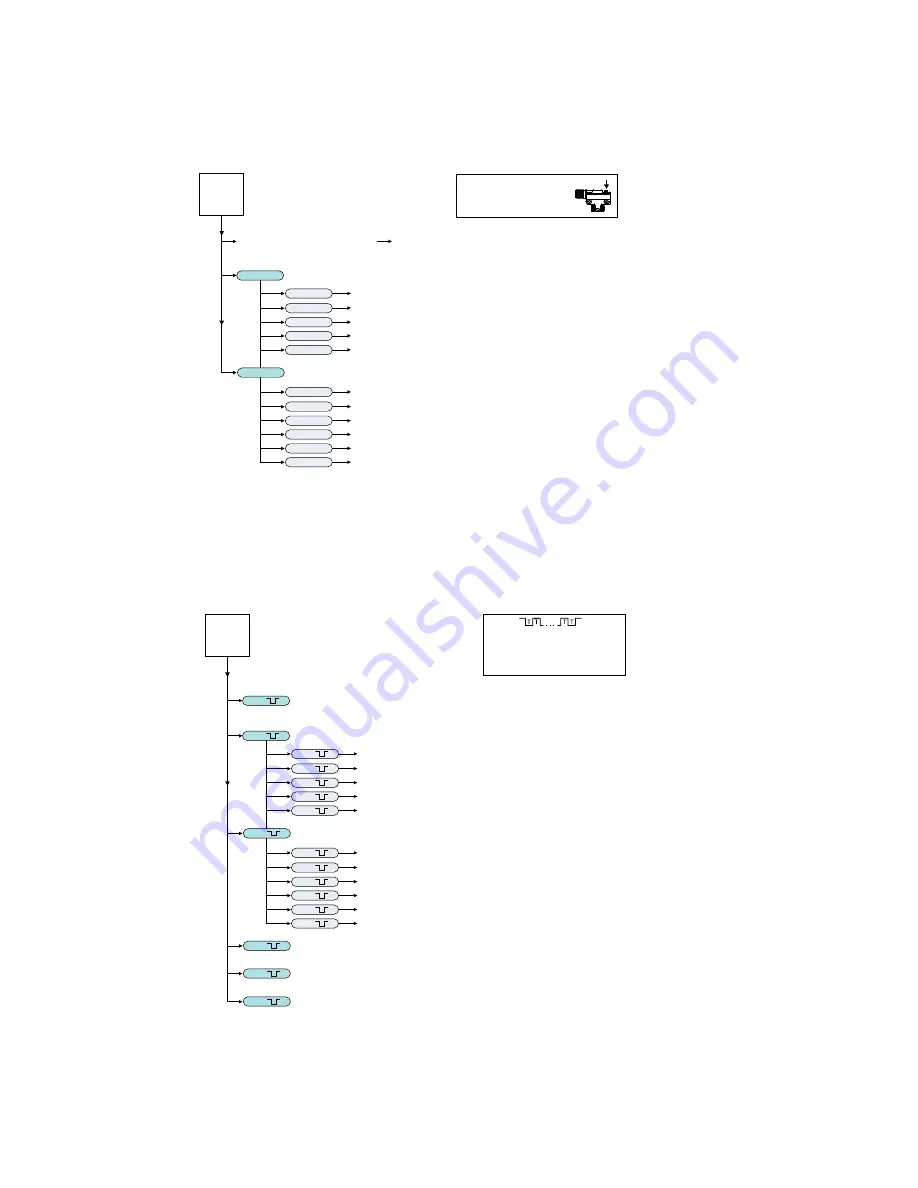

Push Button Configuration

Use the push button to configure the sensor. Click the push button according to Push Button Input Flowchart. After a configuration

has been selected the sensor flashes both the green and amber LED to show which configuration was selected followed by a rapid

flashing of both the green and amber LED in unison to show acknowledgement and acceptance of the configuration.

Unlock push buttons (flashing Green and Amber 1X followed by acceptance flash) default

Lock push buttons (flashing Green and Amber 2X followed by acceptance flash)

Enable Auto compensation (flashing Green and Amber 3X followed by acceptance flash)

Disable Auto compensation (flashing Green and Amber 4X followed by acceptance flash) default

Enable 30 ms Off Delay (flashing Green and Amber 5X followed by acceptance flash)

Disable 30 ms Off Delay (flashing Green and Amber 6X followed by acceptance flash) default

Click 2X

Basic Configuration (alternating flashing Green and Amber LEDs at 1Hz)

Advanced Configuration (simultaneous flashing both Green and Amber LEDs at 1Hz)

Press and hold push button > 2 sec.

Hold is > 2 sec. and < 4 sec.

Click is > 40 ms and < 800 ms

User Interface Push Button

(configuration using push button)

Initiate LIGHT/DARK SET

Click 2X

Click 1X

Set output to Light Operate (flashing Green and Amber 1X followed by acceptance flash)

Set output to Dark Operate (flashing Green and Amber 2X followed by acceptance flash) default

Click 4X

Click 3X

Set offset to 8% offest (flashing Green and Amber 3X followed by acceptance flash)

Set offset to 16% offest (flashing Green and Amber 4X followed by acceptance flash) default

Sensor

Push

Button

Click 5X

Set offset to 32% offest (flashing Green and Amber 5X followed by acceptance flash)

Click 3x

Click 2X

Click 1X

Click 4X

Click 3X

Click 5X

Click 6X

Figure 1. Push Button Input Flowchart

Remote Input Configuration

Enabling the remote input wire is done using IO-Link. Use the remote input function to configure the sensor remotely. Connect the

white wire of the sensor as shown in the wiring diagram. Pulse the remote line according to the Remote Input Flowchart. After a

configuration has been selected, both the green and amber LEDs will flash to show which configuration was selected, followed by

a rapid flashing of both the green and amber LED in unison to show acknowledgement and acceptance of the configuration.

2x

1x

Unlock push buttons (flashing Green and Amber 1X followed by acceptance flash) default

Lock push buttons (flashing Green and Amber 2X followed by acceptance flash)

4x

3x

Enable Auto compensation (flashing Green and Amber 3X followed by acceptance flash)

Disable Auto compensation (flashing Green and Amber 4X followed by acceptance flash) default

5x

Enable 30 ms Off Delay (flashing Green and Amber 5X followed by acceptance flash)

6x

Disable 30 ms Off Delay (flashing Green and Amber 6X followed by acceptance flash) default

1x

2x

Basic Configuration (alternating flashing Green and Amber LEDs at 1Hz)

Advanced Configuration (simultaneous flashing both Green and Amber LEDs at 1Hz)

Initiate LIGHT/DARK SET

40 ms < T < 800 ms

Timing between Pulse groups > 1 second

Pulse Timing (T)

(white wire is input wire)

2x

1x

Set output to Light Operate (flashing Green and Amber 1X followed by acceptance flash)

Set output to Dark Operate (flashing Green and Amber 2X followed by acceptance flash) default

4x

3x

Set offset to 8% offset (flashing Green and Amber 3X followed by acceptance flash)

Set offset to 16% offset (flashing Green and Amber 4X followed by acceptance flash) default

3x

Toggle Teach Button Lock/Unlock (flashing both Green and Amber LEDs 4X followed by acceptance flash)

4x

Force Sensor to Maximum Gain Condition (DARK SET) Without LED Brightness

Change (flashing both Green and Amber LEDs 6X followed by acceptance flash)

5x

Reset to Factory Defaults (flashing both Green and Amber LEDs 8X followed by acceptance flash)

8x

Remote

Input

Wire

5x

Set offset to 32% offset (flashing Green and Amber 5X followed by acceptance flash)

(configuration using remote input wire)

Figure 2. Remote Input Flowchart

WORLD-BEAM QS18E Clear Object Detection

P/N 194469 Rev. C

www.bannerengineering.com - Tel: +1-763-544-3164

3