4.3.2 Initial Power-Up

1. Inspect the area near the light screen for reflective surfaces, including work pieces and the guarded machine.

Reflective surfaces may cause light beams to reflect around a person in the light screen, preventing the person

from being detected and not stopping the machine motion (see

Adjacent Reflective Surfaces

on page 16).

2. Eliminate the reflective surfaces as much possible by relocating, painting, masking, or roughening them. Remaining

problem reflections will become apparent during the trip test.

3. Verify that power is removed from the EZ-SCREEN Type 2 System and from the guarded machine and that the

OSSD safety outputs are not connected.

4. Remove all obstructions from the light screen.

5. Leaving power to the guarded machine Off, make power and earth ground connections on both the emitter and

receiver cables (see

Generic Emitter Wiring Diagram

on page 34).

6. Power up the EZ-SCREEN Type 2 System only.

7. Verify that the input power is present to both the emitter and the receiver. At least one indicator on both the

emitter and the receiver should be On and the start-up sequence should cycle.

8. Watch both the emitter and the receiver LED indicators to determine the light screen alignment status.

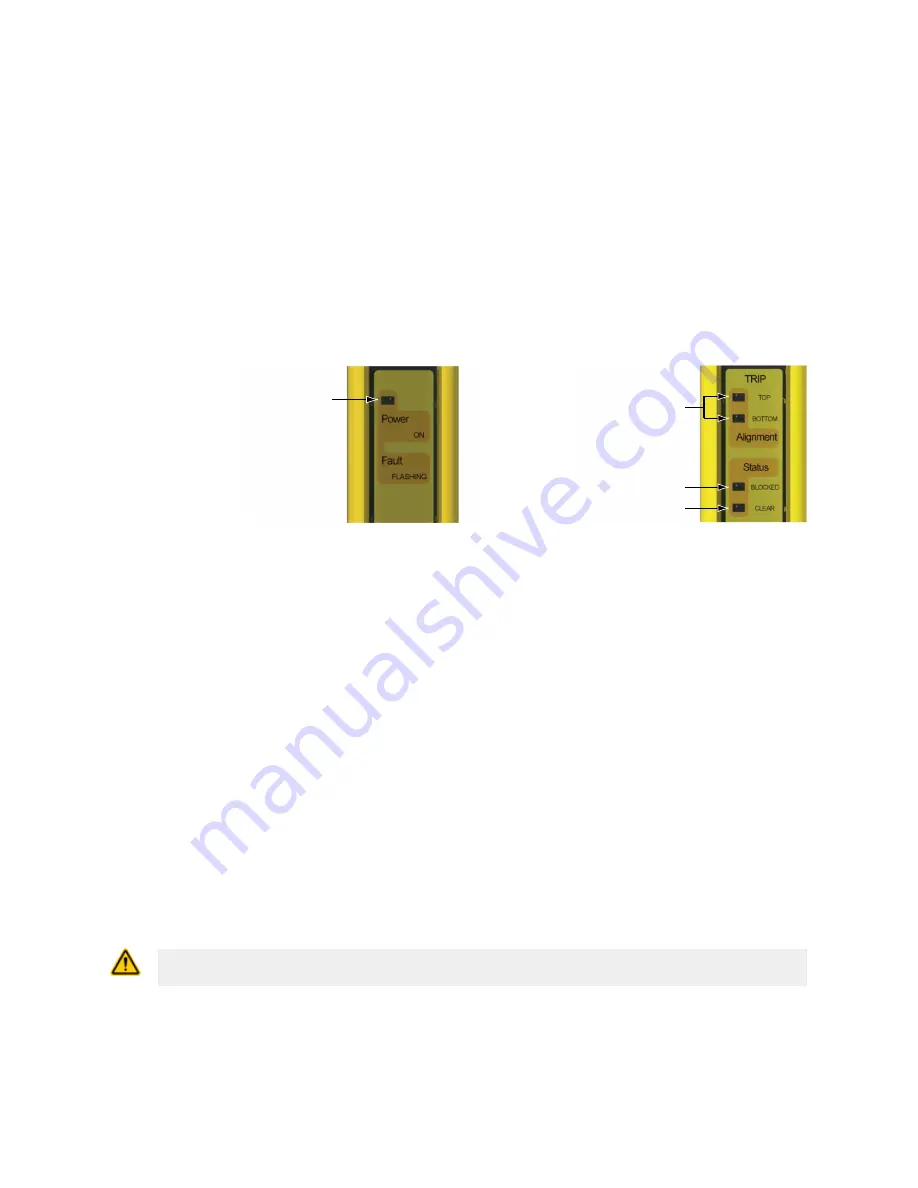

Power/Fault LED (Green)

Figure 12. Emitter Status Indicators

Alignment LEDs

(Yellow)

Status Blocked LED (Red)

Status Clear LED (Green)

Figure 13. Receiver Status Indicators

•

Lockout Condition—on the emitter, the green Power indicator is flashing or on the receiver, the red

Status Blocked indicator is flashing. See

Troubleshooting and Lockout Conditions

on page 40 for

diagnostic information.

•

Normal Operating Mode—to the emitter, the green Power indicator is ON.

•

Test Mode, input fault: On the receiver, the red Status Blocked indicator is On and the green Status Clear

indicator is On. Test input open at power-up.

•

Receiver Latch Condition, all optical beams clear—on the receiver, the red Status Blocked indicator is

On and both yellow Alignment indicators are flashing. For Latch Output receivers, the outputs are On only

when all beams are clear and after a manual reset. If a reset routine can cause a Clear (Run) condition,

optimize the alignment as described in

Optical Alignment

on page 26. If a Clear (Run) condition cannot be

achieved, see “Blocked condition” below.

•

Clear (Run) Condition—on the receiver, the green Status Clear indicator is On Green, and both yellow

Alignment indicators are On. To optimize alignment and maximize excess gain, slightly loosen the four

sensor mounting screws and rotate one sensor left and right, noting the positions where the red Status

Blocked indicator turns On; repeat with the other sensor (see

Optical Alignment

on page 26). Center each

sensor between those two positions and tighten the end cap mounting screws, making sure to maintain the

positioning as the screws are tightened. The sensor lenses should directly face each other. Proceed to

Trip

Test

on page 28 once optimum optical alignment is verified.

•

A Blocked Condition—on the receiver, the red Status Blocked indicator is On, and both yellow Alignment

indicators are On or Off. To remedy, perform the

Optical Alignment

on page 26 procedure.

4.3.3 Optical Alignment

CAUTION: Ensure that no individuals are exposed to any hazard if the OSSD outputs turn ON

when the emitter and receiver become aligned.

EZ-SCREEN

®

Type 2 Light Screen

Phone: 800.894.0412 - Fax: 888.723.4773 - Web: www.clrwtr.com - Email: [email protected]