13

MAINTAINANCE

The RAM T1/T2 is a sealed unit, quality precision engineering will ensure

many years of trouble free service if the following points are adhered to.

: Keep the piston rod free from damage

: Avoid exposing the unit to salt water.

Perform the following checks regularly:

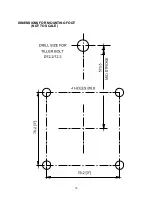

: Check the security of the mounting bolts and tiller pin.

: Examine electrical cables and connections for damage and corrosion.

: Lubricate the mounting pin and rod end with marine grade grease.

SERVICING

In the unlikely event that new seals are required a kit is available:

Hydraulic Projects Ltd Part No. ML+40sk.

Please quote your units serial number when ordering (Ref. page 19).

Caution

For filling and bleeding a special tool is required:

Hydraulic Projects Ltd Part no. R4051.

Failure to use this tool may result in damage to the actuator.