13 / 22

98318_201204

Assistance Service to repair the fault.

MAINTENANCE

The burners do not require particular servicing. It is good practice,

however, to perform the following operations, at least at the end of

the heating season:

1) Disassemble the filters, nozzle, turbulator disk and the

ignition electrodes and clean thoroughly with solvents (petrol,

trichloroethylene, oil). Avoid using metallic tools to clean the

nozzle (use wood or plastic).

2) Clean the photocell.

3) Have the boiler cleaned and the chimney as well, if necessary.

Note:

The nozzle or nozzles should be replaced at least every

two heating seasons. The replacement might be required more

frequently.

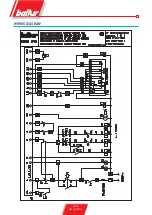

DESCRIPTION OF THE TWO-STAGE

BURNER OPERATION

The two stage burner always ignites with a limited amount of air and

fuel (1

st

flame) and, subsequently, after a few seconds, it will switch

to full air and fuel operation (2

nd

flame).

The ignition of the 2

nd

flame is subject to the authorisation of the

control box and control device (pressure switch or thermostat).

When the burner works at full rate it will remain in this position until

it reaches the pressure or temperature limit pre-set on the control

device (pressure switch or thermostat). The control device trips,

disconnecting the 2

nd

flame (fuel and air), when the limit to which it

has been pre-set is reached. Then the burner works only with the

1

st

flame.

Normally the 1

st

flame alone is not sufficient to keep the temperature

or the pressure at the required limit, and so it will decrease until it

reaches the limit to which the control device of the 2

nd

flame (pressure

switch or thermostat) re-activates the total fuel and air delivery rate.

If the burner operates only with the 1

st

flame, it will stop completely

when the pressure or the temperature reaches the tripping point set

on the control device (pressure switch or thermostat).

The burner starts up automatically again when the pressure or

temperature falls below the limit to which the pressure switch or

thermostat has been pre-set.

Note:

It is normally not advisable to connect a burner working on

a boiler for heating water for two-flame working. In this case

the burner works (sometimes for long periods of time) with one

flame alone, the boiler is insufficiently loaded and consequently

the fuels come out at an extremely low temperature (lower than

180°C) generating soot at the chimney outlet. In addition, when

the boiler is working at lower output than that indicated in the

technical data, it is likely that acidic condensate and soot will

form in the boiler, causing corrosion and clogging. When the

two-flame burner is installed on a hot water boiler for heating

use, it must be connected so that it works normally with both

flames, completely stopping without passing to the first flame

when the pre-set temperature is reached. In order for it to work

in this way, do not install the second flame thermostat, and make

a direct bridge connection between the equipment terminals.

This ensures that only the capability of the burner to ignite at

low capacity is used for a gentle ignition, which is essential for

boilers with a pressurised combustion chamber and also very

useful for normal boilers with depression combustion chamber.

The ignition start/stop command is subject to the usual operating

or safety thermostats.