XX & CH CHARBROILER OPERATION MANUAL

2

INSTALLATION INSTRUCTIONS

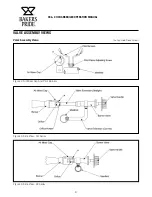

Gas Connection:

The gas pressure regulator supplied must be installed

at the gas inlet of each broiler. Each regulator is

adjusted to yield a manifold pressure of 5 in. water

column for natural gas or 10 in. water column for

propane gas. No pressure regulator is required for

propane gas in Canada.

Recommended minimum gas supply lines are listed below

All XX Models

CH-4 thru CH-8

CH-10 thru CH-16

3/4”

1”

1 1/2”

General:

The instructions in this manual apply to all XX series and

CH series Broilers.

The XX series may include the following options:

Ceramic briquettes designated by a GS Suffix on the

model number.

Installation:

(a) In USA, INSTALLATION of this broiler must

conform with the latest edition of the National Fuel

Gas Code, ANSI Z223.1 and/or local codes.

(b) In CANADA, INSTALLATION must conform with

the latest edition of the National Gas Installation

Code, CAN/CGA-B149.1 or the Propane

Installation Code, CAN/CGA-B149.2, as applicable

and/or local codes.

(c) In MASSACHUSETTS, All gas products must be

installed by a “Massachusetts” licensed plumber

or gas fitter. Ventilation hoods must be installed in

accordance with NFPA-96, current edition, with

interlocks as described in that standard.

Acceptable Clearances:

Due to intense heat generated by radiation, these

broilers should be installed in non-combustible locations

only including above the grate level.

Minimum Clearance From Non-Combustible

Construction.

Series

Right

Left

Back

XX

0”

0”

0”

CH

0”

0”

0”

For units using propane gas, supply lines less than

1/2” inside diameter should not be used, even for a

small unit.

On the XX and CH series, the gas connection is located

on the right rear of the unit.

Be sure to cap whichever side is not connected.

CAUTION

When making gas pipe connections, pipe joint

compound resistant to the action of liquefied petroleum

gases should be used.

The broiler and its individual shutoff valve must be

disconnected from the gas supply piping system during

any pressure testing of that system at test pressures in

excess of 1/2 psig (3.45 kPa).

The broiler must be isolated from the gas supply piping

system by closing its individual manual shutoff valve

during any pressure testing of the gas supply piping

system at test pressures equal to or less than 1/2 psig

(3.45 kPa).

Burners:

Check to see that AIR MIXER CAPS on the front of

all burners are tightened and adjusted, allowing half

the opening to show. Install the burners and deflector

shields first following the steps below.

(a) Install all burners with deflector shield assemblies

attached.

(B) Place the front of the burner into the valve

assembly by fitting the center hole of the mixer

cap over the brass orifice.

(c) Drop the rear end of the burner over the burner

support pin on the back of the unit.

A shut-off valve in a readily accessible location

must be mounted on the gas supply line before

the unit.

NOTICE