5 | Baker Hughes

Copyright 2021 Baker Hughes Company. All rights reserved.

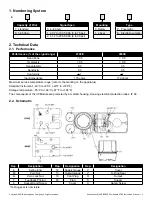

7. INSTALLATION and START UP

These operations must be put into service in conformance

with

EN/IEC 60079-17

and / or national and local regula-

tions applicable for explosive atmospheres.

Before carrying out any work on the device, check that

the local conditions in the potentially explosive atmo-

sphere zone permit the safe opening of the covers.

7.1. Installation

Explosionproof instrument can be installed in

flammable gas explosive atmosphere groups IIC for

the zones 1 and 2 or in flammable dust explosive

atmosphere group IIIC zones 21 and 22. Intrinsically

safe instrument can be installed in flammable gas

explosive atmospheres groups IIC for the zones 0,

1 and 2 or in flammable dust explosive atmosphere

group IIIC zones 20, 21 and 22.

Note: Since the apparatus has multiple certifica-

tions: “ia”, “db” and “tb”, it is recommended that the

type of installation “Ex ia”, “Ex db” and “Ex tb” is

identified on, or next to the apparatus.

7.2. Start-up

Note: Before start-up, proceed, if required, with

instrument calibration as per

§ 8

and/or ensure that all

the safety instructions in the preceding paragraphs have

been strictly followed.

• Before switching on or after doing any work on

the device, always tighten the cover (C) with a

seal (J) in good condition and put back the safety

screw (V).

• Check that the cable gland is certified for the

intended use and that the electrical data are

suitable for the operating zone.

8. CALIBRATION OF THE

4700E/4800E POSITIONER

• Comply with current national and local regula-

tions for electrical installation work.

• Comply with national and local explosive atmo-

sphere regulations.

• Before carrying out any work on the device,

power off the instrument or make sure that the

local conditions in the potentially explosive

atmosphere permit the safe opening of the

cover.

• Before switching on or after doing any work on

the device, always tighten the cover (C) with a

seal (J) in good condition and put back the safety

screw (V).

The positioner mounted on the valve is factory calibrated.

If it is supplied alone, calibration will be carried out by the

customer, as follows:

• Make the electrical and pneumatic connections,

see

§ 4

and

§ 6

.

• The zero is set using the nut (4b). Adjust the nut (4b)

so that the valve is close for the signal value that

corresponds to the closure of the valve.

• The span is adjusted using the spring (5). Turn the

spring (5) on the spring end (4), to increase or reduce

the number of active coils, thus reducing or increasing

the stiffness of the spring. These operations are

carried out

to adjust the span so as that the valve describes its

entire stroke for the full range of the control signal.

• These two operations are repeated until the correct

settings are obtained.

• Lock the zero lock nut (4c) and the socket head

screw (8)

Note: The Model 4000 I/P Converter does not require

any adjustment.

9. MAINTENANCE SERVICE

• Comply with current national and local

regulations for electrical installation work.

• Comply with national and local explosive

atmosphere regulations.

• Before carrying out any work on the device,

power off the instrument or make sure that the

local conditions in the potentially explosive

atmosphere permit the safe opening of the cover.

• Before switching on or after doing any work on

the device, always tighten the cover (C) with a

seal (J) in good condition and put back the safety

screw (V).

9.1. General rules

These operations must be put into service in conformance

with

EN/IEC 60079-17

and / or national and local regula-

tions applicable for explosive atmospheres.

9.2. Before maintenance activity

Before carrying out any work on the device, check that

the local conditions in the potentially explosive atmo-

sphere zone permit the safe opening of the cover (C).