Manager

:

H

ear

ing pr

ot

ec

tion m

us

t be w

or

n at

al

l tim

es

.

Mak

e s

ur

e w

or

k ar

ea i

s c

lear

from

obj

ec

ts t

o s

av

e t

rippi

ng.

O

TH

ER

H

AZ

AR

D

S,

N

O

ISE,

M

EDI

UM

Saf

et

y gl

ov

es

, s

hoes

, pant

s m

us

t be w

or

n.

NE

W

M

ACHI

NE

RY

HA

ZA

RD I

DE

NTI

FI

CA

TI

O

N,

A

SS

ES

SM

ENT & CO

NTRO

L

Item

Aut

hor

ised and s

igned by

:

DUS

T.

Saf

et

y of

fic

er

:

D

ev

el

oped i

n C

o-

oper

at

ion B

et

w

een A

.W

.I.S

.A

and A

us

tral

ia C

ham

ber

of

Manuf

ac

tur

es

Thi

s pr

ogr

am

is

bas

ed upon t

he S

af

e W

or

k A

us

tral

ia,

C

ode of

P

rac

tic

e -

Managi

ng R

isk

s of

P

lant

in t

he W

or

kpl

ac

e (

W

H

SA

2011 N

o10 )

PL

AN

T SA

FET

Y PR

O

G

R

AM

No

.

H

az

ar

d

Id

en

tifi

ca

tio

n

P

ow

er

H

am

m

er

ST

R

IKI

N

G

O

(R

ec

om

m

ended f

or

P

ur

chas

e /

B

uy

er

/ U

ser

)

Pow

er

ham

m

er

m

us

t be us

ed w

ith ex

trem

e pr

ec

aut

ion and i

n a c

ont

rol

led env

irom

ent

.

Assessm

en

t

H

az

ar

d

R

isk

C

on

tr

ol S

tr

ate

gie

s

W

ear

s

af

et

y boot

s.

LO

W

B

CRUS

HI

NG

H

IG

H

Ens

ur

e m

ac

hi

ne i

s bol

ted dow

n.

F

H

IG

H

25t

h F

ebr

uar

y 2019

Plant

S

af

et

y P

rogr

am

to be r

ead i

n c

onj

unc

tion w

ith m

anuf

ac

tur

es

ins

truc

tions

R

ev

ised D

at

e:

w

.m

ac

hi

ner

yhous

e.

com

.au

w

hi

ner

yhous

e.

co.

nz

Sec

ur

e &

s

uppor

t w

or

k m

at

er

ial

.

Ens

ur

e hand &

finger

s ar

e c

lear

from

m

ov

ing par

ts "

Tool

ing D

ies

"

C

C

U

TT

IN

G

, ST

ABBI

N

G

,

M

EDI

UM

W

ear

gl

ov

es

to pr

ev

ent

c

ut

s f

rom

s

har

p m

at

er

ial

.

PUNCT

URI

NG

M

EDI

UM

Keep hands

c

lear

from

m

ov

ing par

ts.

Ens

ur

e c

or

rec

t t

ool

ing c

lear

anc

e i

s s

et

for

eac

h m

at

er

ial

us

ed.

D

SH

EAR

IN

G

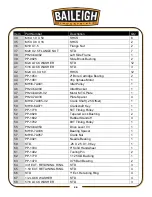

Summary of Contents for PH-28HD-VS

Page 1: ...OPERATOR S MANUAL POWER HAMMER MODEL PH 28HD VS B9045 2018 Baileigh Industrial Inc Rev 02 2018...

Page 18: ...16 16 PLATE ASSEMBLY...

Page 19: ...17 17 UPPER LOWER RAM ASSEMBLY...

Page 20: ...18 18 SPROCKET ASSEMBLY...

Page 21: ...19 19 SPRING ASSEMBLY...

Page 22: ...20 20 LEVER ASSEMBLY...

Page 23: ...21 21 SLIDE STROKE ASSEMBLY...

Page 24: ...22 22 QUICK RELEASE ASSEMBLY...

Page 25: ...23 23 V BELT ASSEMBLY POST...

Page 26: ...24 24 GUARD AND CONTROL BOX ASSEMBLY...

Page 33: ...31 31 NOTES...

Page 34: ...32 32 NOTES...

Page 35: ...33 33...

Page 36: ...34 34...