4

Removing or Replacing the Needle

It is not necessary to completely disassemble the

needle assembly.

1) Remove the handle (50-033) from the back of

the airbrush.

2) Turn the needle chuck (51-010) counter-clock-

wise.

3) Draw the needle out and wipe it clean. (If stuck,

see step 7).

4) Care should be taken that the needle point is not

bent. A bent needle will damage the tip and

cause a rough spray pattern. If bent or damaged

replace needle.

5) Slowly glide the needle into the airbrush while

holding the trigger (50-019) in place, until the

needle stops. Do not apply pressure or force the

needle.

6) Once the needle is in position, tighten the needle

chuck (51-010), replace handle (50-033).

7) If in step 3 the needle is stuck in the airbrush,

carefully grasp the end of the needle with a pair

of pliers and twist in a counter-clockwise direc-

tion to release the needle and remove.

8) Inspect the hardened paint, which causes the

needle to bind. If there is a residual stain on the

needle, it can be polished off using a pink eraser.

Hold the needle flat on a worktable. Run the pink

eraser slowly by rolling it towards yourself and

repeat the process. Be careful not to be bend the

tip. Remove all eraser particles by running the

needle between your thumb and forefinger.

Repeat steps 4 through 6.

Spray regulator should be cleaned using a soft bris-

tle brush. Insert into the cavity of the spray regula-

tor and rotate until the paint is removed.

A bent needle will prevent you from airbrushing a

fine line and will cause an erratic direction of spray.

A bent needle does not always have to be discard-

ed. Place the needle on a firm surface at the angle

of the tip. Straighten the bent needle by running

your fingernail across it on a firm surface while you

turn the needle slowly. Run your fingernail from the

body of the needle outwards toward the tip.

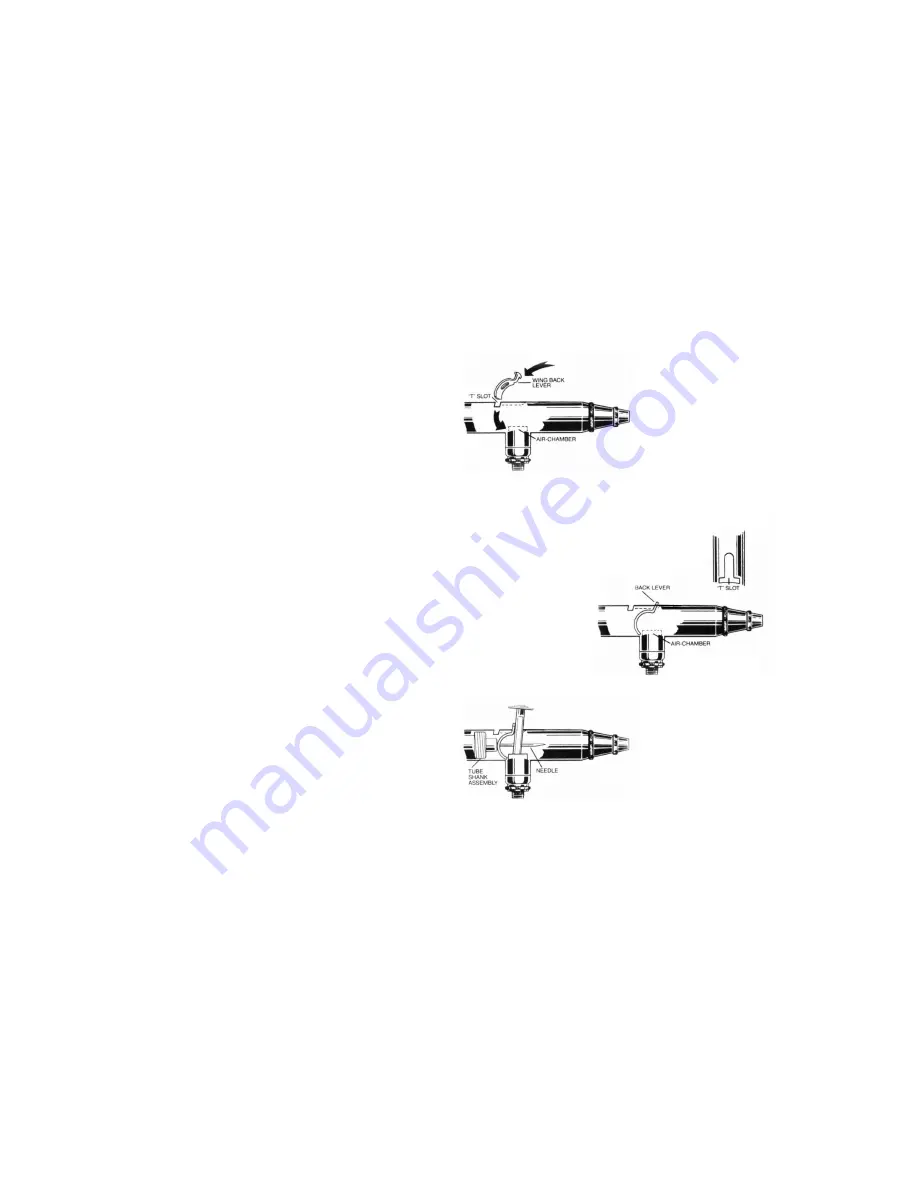

1). Remove handle,

loosen the needle

chuck (51-010), with-

draw needle. Remove

trigger (50-019),

unscrew tube shank

(50-030) assembly.

Removing the Tube Shank Assembly, Trigger and

Back Lever

3). To rein-

sert trigger, pull back

on winged back lever

and insert trigger

into place. Make

sure the trigger is

properly seated.

After inserting trigger, insert needle by gently pushing

forward with index finger until needle stops at the paint

tip, tighten needle chuck (51-010), and replace handle

(50-033).

2). Insert winged back lever (50-042) into

“T” slot at top of airbrush body and move

forward (fig 1). Make sure back lever is

behind the air chamber

(as shown in fig 2).

Screw in tube shank and

entire assembly.

TOP VIEW

Figure 1

Figure 2

TRIGGER TENSION

Your Model 150

™

airbrush has been set with

maximum trigger tension which should be suitable

for most users. If less return spring back pressure is

desired, the spring screw (50-031) can be partially

unscrewed to lessen the spring pressure. Do not

unscrew the entire tube shank (50-030) assembly to

release pressure on the Model 150

™

. If the tube

shank is not seated firmly in the body of the

airbrush, it may spin when trying to loosen the needle

chuck.

Prepare the object to be painted, masking off any

area that should not be painted (be sure object is

clean and free of dust, grease, etc.). Small objects

such as models, etc. should be hung or placed on a

pedestal so all areas to be sprayed can be easily

reached (a stand may be fashioned from an

ordinary wire coat hanger or bottle etc.). Hold the

PAINTING PROCEDURE FOR THREE DIMENSIONAL OBJECTS

tip of the airbrush about 4 to 6 inches from the

surface. Use short strokes, moving the airbrush

constantly at a steady rate parallel to the surface.

Don’t spray too heavily. Apply a light coat, let dry,

then apply another coat and continue until the

desired coverage is achieved.