8) Drain old oil filters of all free flowing oil prior

to disposal. Place used oil in appropriate

containers and deliver to an approved

recycling collection facility.

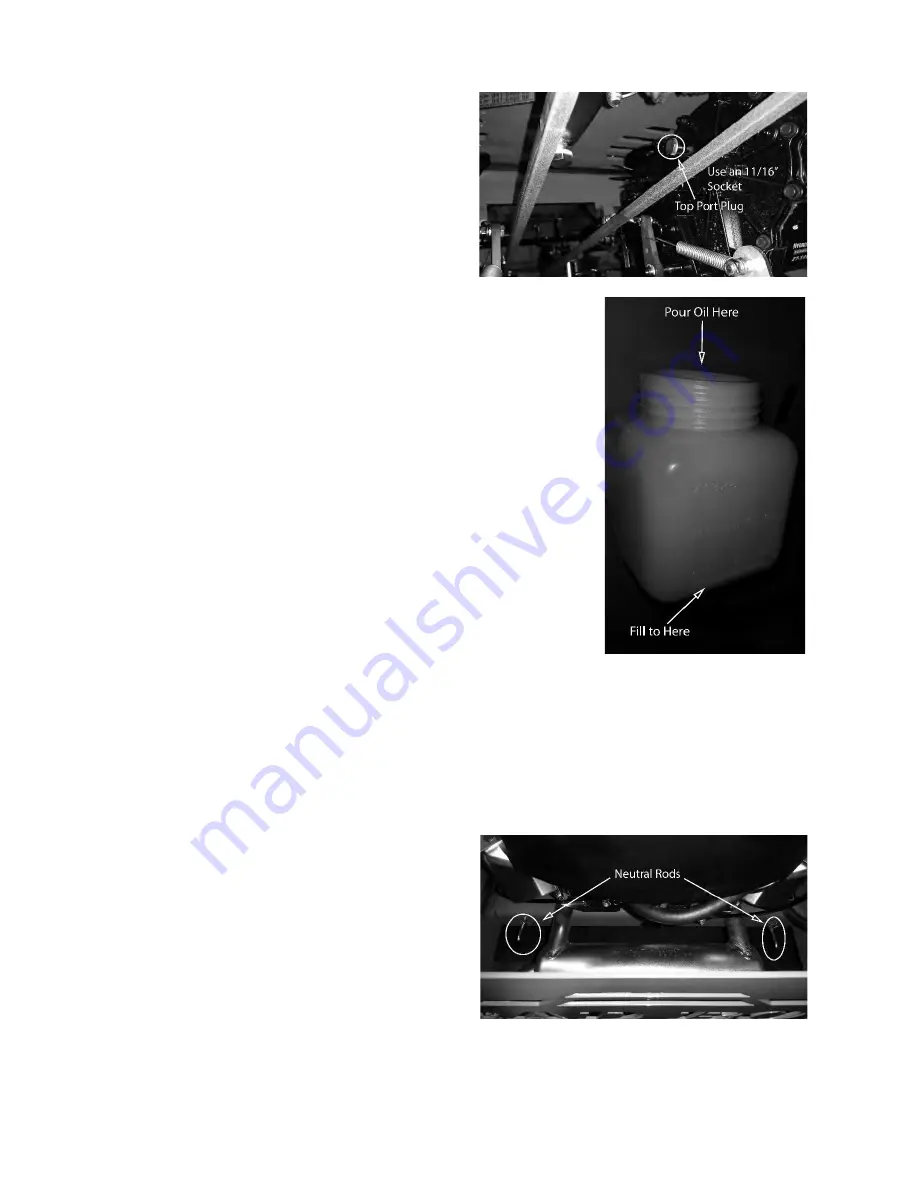

9) Remove the top port plug from the left side

and right side transaxles prior to filling with

oil. This will allow the transaxles to vent

during oil fill and prevent any air lock within

the transaxles.

10) Fill with 20W-50 motor oil

(Bad Boy

Hydrostatic oil is recommended) through the

hydraulic fluid reservoirs until it just appears at

the bottom of each transaxle’s top port (approximately 2

quarts per transaxle, 4 quarts total). Install the top port

pug into each transaxle as the oil level reaches this port.

11)

Install and torque the top port plugs to 180 in. lbs. (20.3

Nm).

12)

Continue to fill the transaxle through the hydraulic fluid

reservoirs until the “Full Cold” line is reached on the

hydraulic fluid reservoirs.

13)

Re-install the caps on the hydraulic fluid reservoirs.

14)

Now we need to purge the air from the transaxle. With

your mowers tires off the ground disengage the brake

and start the engine.

15)

Pull the neutral bypass levers which are located on each

side of the muffler. Then slowly move the drive arms in

the forward and reverse direction 5 to 6 times.

16)

Push the neutral bypass levers back into place. Move

the drive arms forward and backward 5 to 6 times

slowly. Check the oil level, and add oil as required after

stopping the engine.

17)

It may be necessary to repeat steps 15 and 16 until all

the air is completely purged from the system. When the

transaxle operates at normal noise levels and moves

smoothly forward and reverse at normal speeds, then

the transaxle is considered purged.

Under the rear of the mower, you will find the two

levers shown in the image. These bypass levers

serve as a neutral for moving the mower while the

engine is not running. Pull the levers out and lock

them into place to activate the bypass.

PAGE

20

Summary of Contents for COMPACT OUTLAW

Page 30: ...PAGE 30...