CO2 Analyzers 3100 & 3150

Instruction 19-9339

25

5.9.2.6 Logging

Data logging mode can be started or stopped via “KEY 6 - LOGGING”

which is accessed from the “UTILITIES” menu. Press “KEY 4 -

START/STOP LOGGING” to start and stop data logging.

While in data logging mode, the instrument will automatically record

data at the pre-set intervals including running the pump for a preset

time period. Active logging mode is indicated on the “MAIN READ

SCREEN” by its icon. The operator is able to edit the default ID,

pump run-time, interval, and start/stop logging.

1) From the “MAIN READ SCREEN” press the “MENU” key on the

instrument panel.

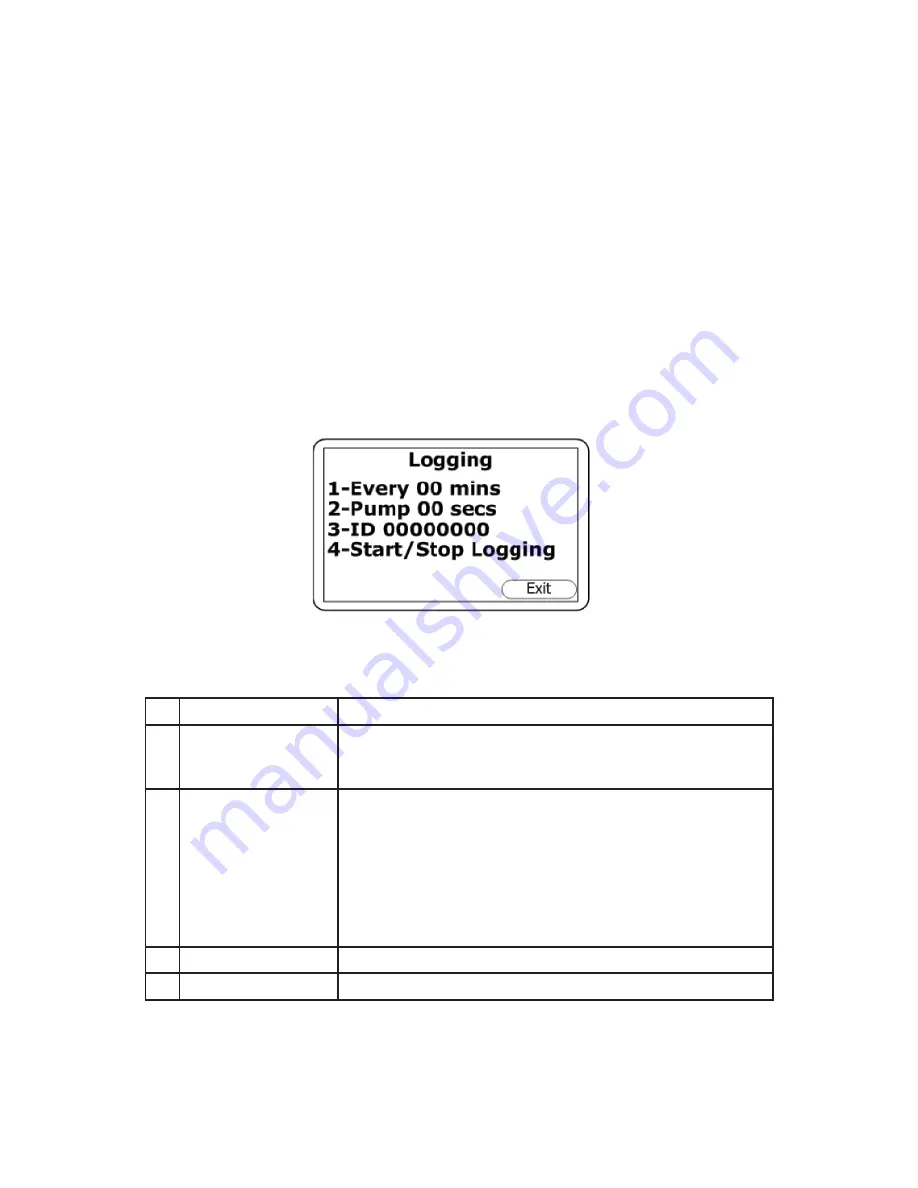

2) Press “KEY 6” to display the “LOGGING” menu and the following

screen will be displayed:

3) Select the desired option by pressing keys “1” through “4”. Then

enter the appropriate setting using the keypad followed by the

“ENTER” key.

Setting

Use

1

Every 00 mins.

Press “KEY 1” to enter the time in minutes for the timeframe

between sample readings. The interval controls the reading

frequency in minutes, i.e. every 10 minutes.

2

Pump 00 secs.

Press “KEY 2” to enter the time in seconds for the length of

time you wish the pump to run when taking a sample read-

ing. The pump run-time is the time in seconds for which the

pump runs prior to the reading being stored. This

fi

gure will

also need to take into account the length of sample tube and

the volume of the sample gas. For example, there is little

point setting a pump run-time of 10 seconds if it takes 30

seconds to draw in a new sample.

3

ID 00000000

Press “KEY 3” to create an 8-digit numeric ID code.

4

Start/Stop Logging

Press “KEY 4” to start and stop data logging.

NOTE:

Data logging mode is automatically stopped when the

instrument is switched off or the logging parameters are

edited.