Charging the System

1. Evacuate and pressure test the system. This can be

accomplished by charging with nitrogen to 75 lbs

and checking your gauges for any sign of a leak.

Evacuate the system to 500 microns.

2. Charge the system with R134A until the sight

glass goes clear. Initial charge will be 6.3 pounds

of 134A; the pumpdown capacity of the receiver.

It is very important not to over charge this system.

As soon as the bubbles in the sight glass disappear,

discontinue charging. Over-charge will result in an

ice block in the evaporator.

3. Adjust the TXV to 12-14 degree’s of superheat.

Take your suction pressure and temperature reading at the condenser,

and add two pounds to it for the pressure drop.

Take the difference between actual temperature and

your reading from a PT chart to calculate.

4. System Start up. Before replacing stainless steel

enclosure cover, power up the system to make sure

water solenoid is opening correctly. The misting

nozzle will be open. Remove power and replace the

cover. Power up the evaporator, and let the system

pull down. At temp set point the refrigerant solenoid

will close and the system will pump down and shut

off the condensing unit.

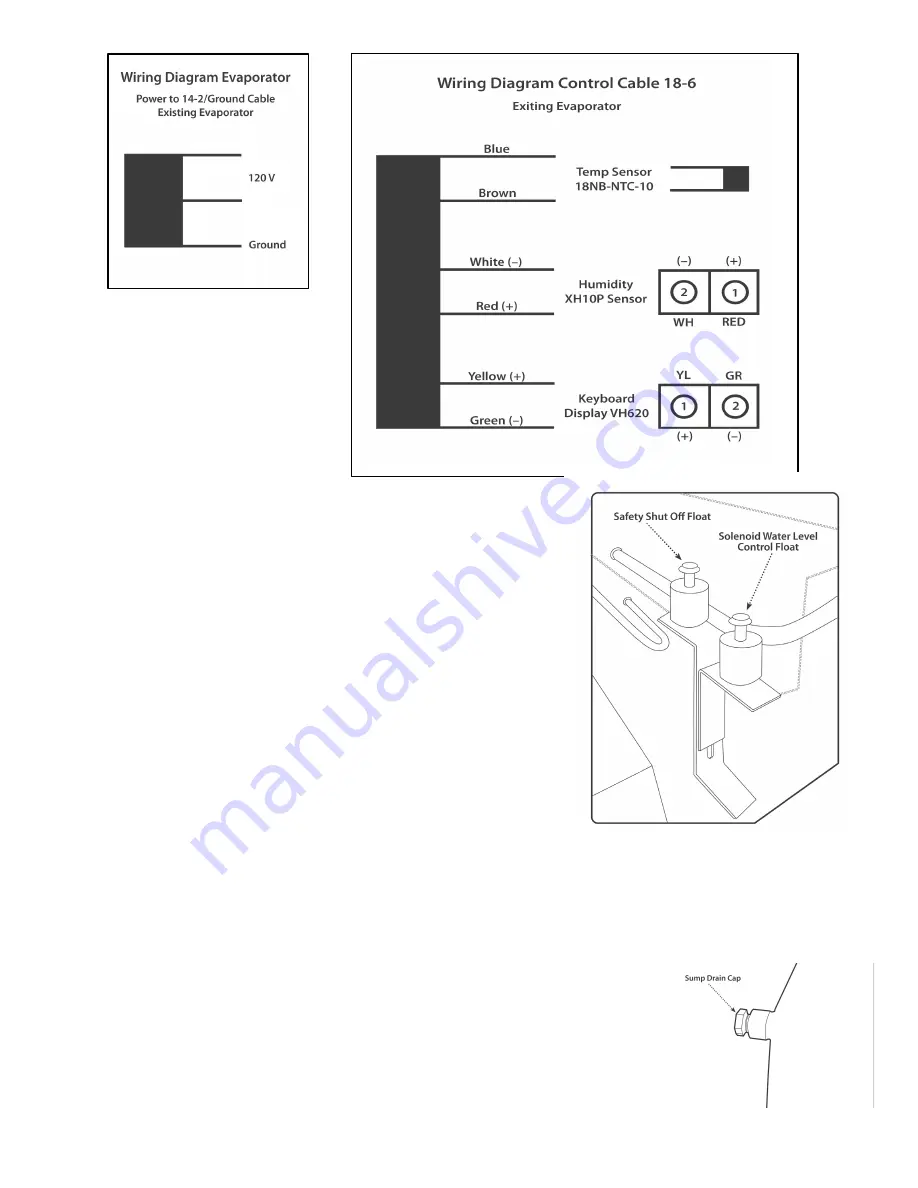

5. Check level of safety float.

Breakers. We recommend a 30a fused disconnect.

Maintenance and Troubleshooting

Have your system checked each year by a certified refrigeration technician.

He should:

1. Clean the indoor and outdoor coils

2. Change the water filter on the Humidification models, and change out

the humidification mister head

3. Drain the Stainless steel sump (diagram #3), and clean it if necessary.

6