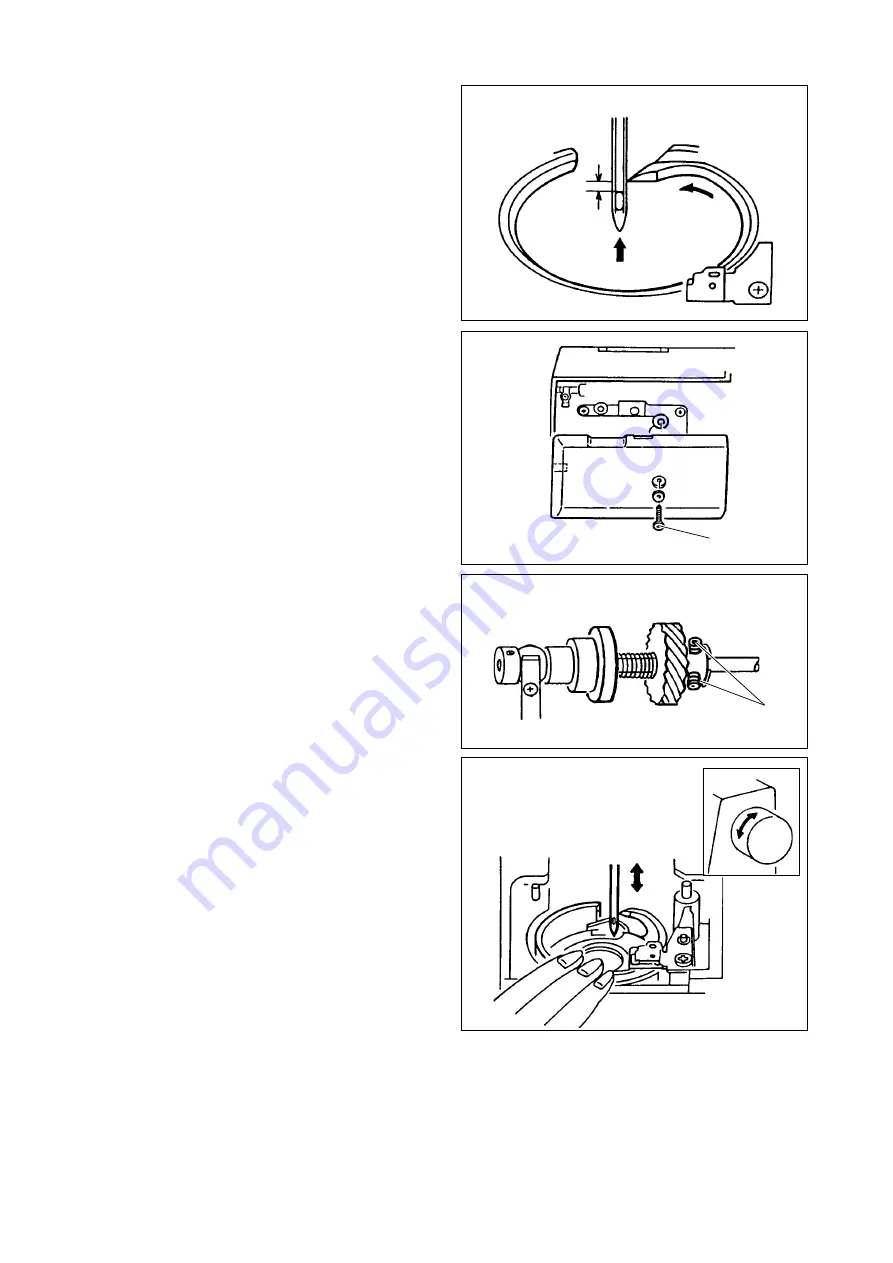

fig. 3-1

fig. 3-2

a

fig. 3-3

b

fig. 3-4

1.5-2.0 mm

- 7 -

3. TIMING OF THE HOOK

Prior to making this adjustmetnt, be sure that the needle

bar is set at the correct height. (See sec. 1)

Check the timing of hook as follows:

1. Remove the needle plate and bobbin holder. (See sec.

1-2)

2. Set the pattern number at “1”. (Straight stitch on left

needle position)

3. Turn the handwheel toward you until the needle is at

its lowest point.

4. Then, turn the handwheel slowly to turn the hook

counter-clockwise until the tip of hook is aligned with

the right side of needle. (fig. 3-1)

At this time, the gap between the tip of hook and the

top edge of needle eye should be 1.5 to 2.0 mm.

If the gap is too small or too large, adjust as follows:

5. Tilt the machine backward.

Remove the bed lid by removing the screw (a) and

sliding bed lid to the left. (fig. 3-2)

6. Loosen the two screws (b) on the lower shaft gear with

a hexagon socket screw key (2.5 mm). (fig. 3-3)

7. Turn the hook race by hand so that the tip of hook will

align with the right side of needle.

In this position, hold the race with your left hand and

turn the handwheel toward you to obtain the correct

gap (1.5 to 2.0 mm). (fig. 3-4)

8. Tighten the screws (b) and check the timing again.

9. Replace the bed lid, bobbin holder and needle plate.