Installation, Operation & Maintenance Manual

INSTALLATION

4

Rev 09/17

1-1/2 inch Vinyl Handrail

Model(s): BHRVE15C-P

installation

Preparation: Verify that all products listed on the packaging slip are included in the package.

Check the products for damage. If product is damaged, contact customer support immediately

to report a freight claim.

Store material in a clean dry place where the temperature is maintained above 50°f (10°C).

Walls and rooms should be maintained at a minimum of 65°f (18°C) for at least 48 hours prior

to installation. Acclimate materials to normal building conditions for at least 24 hours before

cutting and installing.

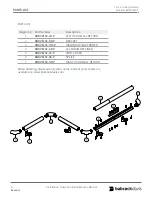

Step 1

Determine top of handrail height and snap a chalk line 2-1/2 inches below for centerline

of mounting hardware, see

fig. 1

.

Step 2

Cut retainer. See

Cutting Adjustment Diagrams and Schedule

for adjustments to

retainer length at wall returns, inside corners and outside corners. Refer to

Minimum

Layout Configurations

and

Clearance with Adjoining Construction

for additional

information. All cuts must be square and deburred.

Step 3

Layout retainer “face up”, mark and drill bracket mounting hole locations. Use groove in

retainer to locate centerline for drilling, see

fig. 2

. Bracket mounting holes must be spaced:

• Not to exceed 32 inches on center

• 1-1/2 inches to 6 inches from end of retainer at returns and corner accessories

• A minimum of 4 inches from end of retainer at splices to avoid interference with splice

hardware (shown in

fig. 5

)

• To align with metal studs (on metal stud construction) or preferably with horizontal

backer plate (by others)

Step 4

Locate and drill bracket mounting holes in wall construction using the retainer as a

template or by careful measurement. Choice of hardware will dictate hole diameter.

Step 5

Insert molded accessories into end of retainer, press firmly to ensure molded part is

seated squarely against the end of the retainer. Drill accessory mounting holes using the

accessory as a template, see

fig. 3

.

Step 6

Attach molded returns, outside corners and inside corners to retainer with accessory

seated firmly and squarely while tightening. Fasten with 1/4 inch machine screw, flat

washers and nylon lock jam-nut provided.

Caution:

Do not use lock washers, use flat washers only. Install a flat washer between nut

and molded tab. Tighten to 10 ft-lbs maximum torque, see

fig. 4

.