Routing Maintenance

28

Daily

Weekly

• Keep the machine clean.

• Check the saw blade for missing teeth and

cracks, see fig 89.

• Spray oil the bare metal surfaces.

• Open the top and bottom wheel covers and clean out

all saw dust.

Monthly

• Open the lower and upper door and check the

condition of the tyres and the drive belt, see figs 88-89-

90.

• Clean impacted ‘crud’ from the tyres, apply a little oil to

the screw threads of the blade and drive belt tensioners.

DO NOT USE OIL near the belt.

• The pivots and the slides of the top wheel mounting

assembly and the captive stub axle of the belt tensioner

in its slot could likewise be lightly oiled.

• Using an air line (wearing goggles) blow out the motor

casing.

Fig 88-89-90

• Check the condition of the tyres (A)

• Check for missing teeth (B)

• Check the condition of the drive belt (C)

A

B

C

Clean out impacted ‘crud’ and saw dust

Clean out impacted ‘crud’ and saw dust

Summary of Contents for SBW-350

Page 1: ...SBW3501B Bandsaw Code 501199 AT M 09 01 2018 REF 508308 ...

Page 4: ...4 5 6 7 What s Included 4 2 2 3 ...

Page 5: ...What s Included 5 10 9 8 15 14 13 12 11 16 17 18 19 20 21 22 23 24 25 26 ...

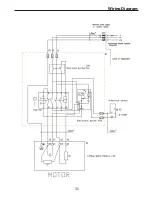

Page 29: ...Parts Breakdown List 29 Continues Over Main Saw Assembly ...

Page 35: ...Wiring Diagram 35 ...