11

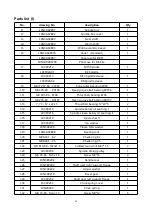

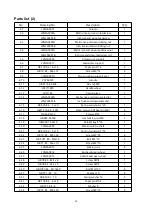

Common trouble problems and their Solutions

Symptom

Possible Cause

Possible Solution

Motor can not

start

1. The power supply is not on.

2. Low voltage.

3. Motor open circuit or loose

connection.

4. The external input socket is

broken.

5. May which switch is bad or

connect line loosen;

1. Turn on the emergency stop button

2. Check that the voltage of the power

supply is correct.

3. Check that all the connections of the

motor are loosened or disconnected.

4. Check and confirm the input socket is

ok.

5. Check switch and the connect lines is

tighten.

Fuse or circuit

breaker

disconnected

1. Wire or plug short circuit

2. Circuit board short circuit

3. Power supply fuse or circuit

breaker incorrect.

1. Check wires and plugs for damaged or

missing insulation and replace them with

extension wires.

2. Check the voltage of the power supply

is correct

3. Check that all connections of the motor

are loose or welded or insulated, and

replace the correct fuse or circuit breaker

in time

Motor

overheating

1. Motor overload

2. Air circulation of motor is

restricted

1. Reduce the load of motor

2. Clean the motor and ensure smooth

circulation of air

The hand wheel

of a transverse

or feed trawl is

too loose

1. The adjusting screw is not in

place.

2. Hand wheel loosened

3. Wire rod assembly old or not

in place

1. Tighten the adjusting screw and

lubricate the bed

2. Tighten the hand wheel knob

3. Tighten all loose knobs on the thread

rod assembly.

The machine

makes constant

noise

1. The gear or bearing is out of

order.

2. The motor is out of order.

1. Replace damaged gear or bearing

2. Replace motor

During

operation, the

machine stops

1. Drilling and milling too deep

2. The wrong speed or feed

speed was used in the drilling

and milling operation.

3. Milling cutter damage

4. Motor damaged

5. Gear damaged

1. Reduce drilling depth

2. Choose the right speed

3. Replacement milling cutter

4. Replacement motor

5. Replacement gear

Finish surface

difference

1. Speed or feed speed error

2. Milling cutter broken or

wrong selected

1. Change the milling cutter by adjusting

the correct speed or feed speed

2. Change the cutter

Difficult to move

the end part on

the guide rail

1. Drying of guideway

2. Z shaft hand wheel to tighten

3. Over compacted with debris

on guide rail

1. Lubricating oil

2. Adjusting screw

3. Cleaning guide

T - type nut is

difficult to fix

1. T type nut defect or damaged

2. T-groove on the wrong

working table

1. Replacement of type T nut

2. Replacement of table or well-used T

slot