6

Assembly

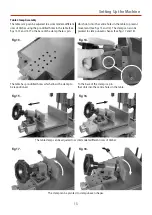

Locate the operating wheel (B), slide it on to the operating

wheel shaft (C) as shown in fig 6 (Note: Make sure the

locating key engages into the shafts machined slot).

Secure using the phillips screw and clamping washer you

removed earlier (See fig 7).

Move the table to the left by turning the operating wheel

(B), thus reveling the grub screw beneath. Locate one of

the two distance stop rods (D) and a ring collar clamp (F),

slide the ring collar clamp (F) onto the distance stop rod

(D) and lightly tighten by turning the lift and shift handle,

see fig 8 on the previous page. Line up the countersink

mark on the rod (D) with the grub screw, (make sure the

grub screw is raised fully) slide the rod (D) into the pre-

drilled hole to the end of casting and tighten the grub

screw (See figs 9,10 and 11) repeat for the opposite side.

Remove locking caphead screw (a) (see page 5), that locks

the morticers head assembly and replace it with the M6 x

30mm lift and shift handle (E) (See fig 12).

Secure the operating wheel (B) using the phillips screw

and clamping screw.

Slide the ring collar clamp (F) onto the distance stop rod

(D) and lightly tighten.

Countersink mark

Grub screw

Fig 7.

Fig 9.

Fig 11.

Fig 8.

Fig 10.

C

F

E

Fig 12.