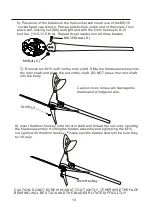

6).Place one of the blades on the hub socket and insert one of the M6-15

socket head cap screws. Place a plastic disk on the end of the screw, then

place self-locking nut (M6) and tighten it with the 5mm hex key to 8-10

foot lbs. (10.5-13.5 N.m). Repeat this procedure on all three blades.

M6-16 Screw ( 6 )

M6 Nut ( 6 )

7). Remove the M16 nut from the rotor shaft. Slide the blades assembly onto

the rotor shaft and place the nut on the shaft. DO NOT press the rotor shaft

into the body.

Caution: over-torque will damage the

blades and wind generator.

M16 NUT

8).Insert the 8mm hex key into the rotor shaft and thread the nut on by spinning

the blades assembly. Holding the blades assembly and tightening the M16

nut lightly with the 8mm hex key. Finally, spin the blades slowly to be sure they

turn freely.

8mm Hex Key

CAUTION: DO NOT SCREW M16 NUT TOO TIGHTLY, OTHERWISE THE FACE

BEARING WILL BE STUCK AND THE BLADES ROTATE DIFFICULTLY!

13

Summary of Contents for AWS400W

Page 2: ...2...