AWS AirBar Operator’s Manual

13

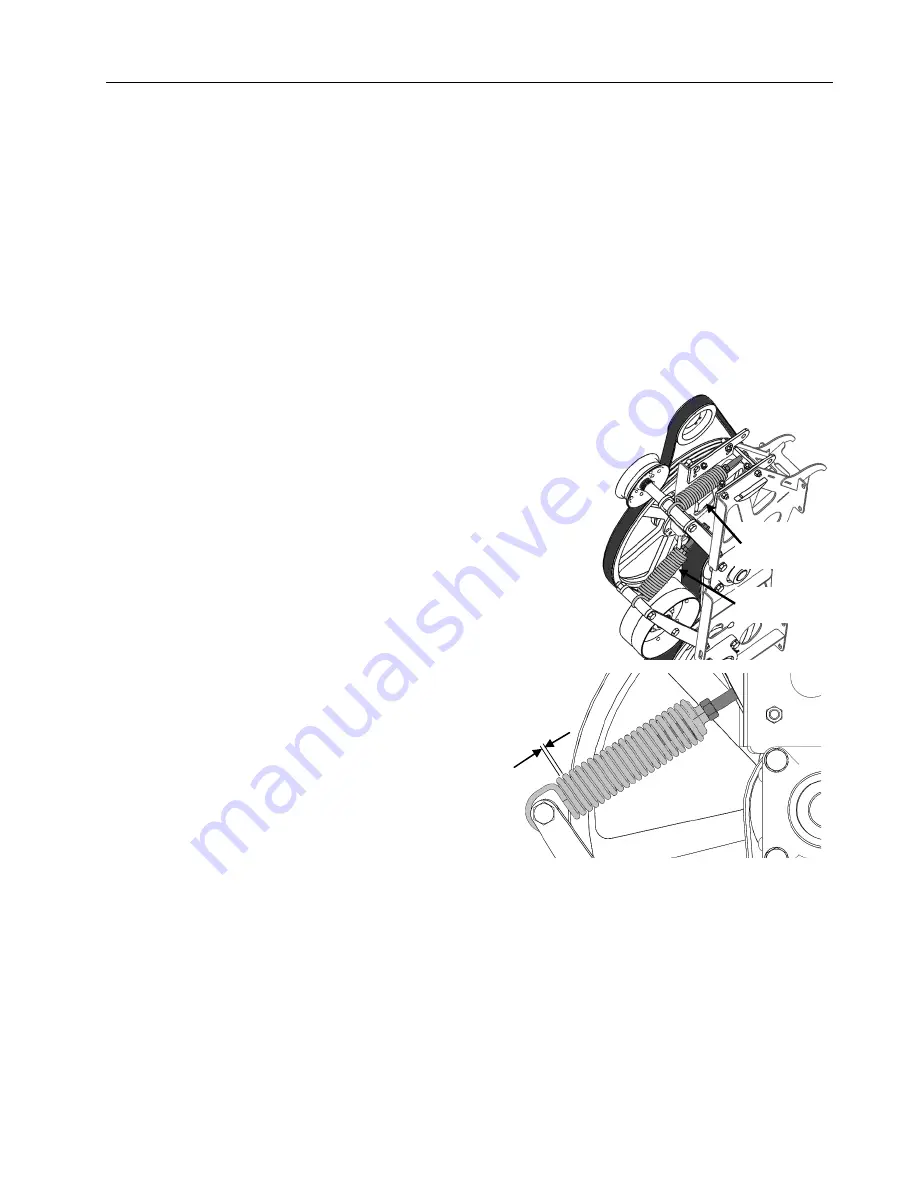

BELT / SHEAVE / IDLER CONDITION

Inspect all belts, sheaves and idlers for good condition.

Belts should appear supple with no shiny appearance on the

drive surface or cracks on the inner or outer surface.

Belts should not sit in the bottom of the sheave grooves or the

inner ribs between grooves should not be worn to a point. If

either of these cases exist, the sheave is worn excessively and

should be replaced.

Idler pulleys should be in-line with the belt running path and

parallel with the sheaves. If the idler is not inline or parallel,

inspect the idler bearing condition or the bronze bushings on

which the idler pivots for wear. Replace as required.

BELT TENSION

Proper belt tension is critical to both optimum performance and

long life of your AirBar system. Loose belts will create excessive

heat and ultimately fail. Belts that are too tight can lead to

accelerated bearing failure.

Belt tension is set using a draw-bolt to extend a spring. The

extended spring maintains tension.

On initial tensioning of new belts, tighten the draw bolt until a

quarter can fit between the coils. Once initial run-in is

completed, maintain a dime-thickness gap in the spring.

It is important to set the secondary belt tension first, then the

primary. Double-check the secondary belt tension after setting

primary tension.

“

Quarter

”

Thickness

–

Initial

“

Dime

”

Thickness

–

Run-In

Primary Tensioner

Secondary

Tensioner

Summary of Contents for AIRBAR

Page 1: ...OPERATOR S MANUAL AWS Airbar Systems Header Mount Fan Version 20200325 ...

Page 2: ......

Page 4: ......