INSTALLATION, OPERATION AND MAINTENANCE MANUAL – ORIGINAL VERSION

AVK GATE VALVES FOR WATER AND FIRE PROTECTION

SERIES 145

Page 7/12

MI GateValve 145 rev. AC 2020 GB

7. REPAIR PROCEDURES

In most cases, in order to keep system downtime to a minimum, complete valve assembly replacement is implemented. This

may also be preferable due to physical access restrictions in the area of the valve. If this is the case, as in all installation/

maintenance and inspection procedures, follow all local installation and safety practices as directed by the authorities having

jurisdiction.

If system downtime is not an issue, the following procedures provide repair instructions for minor issues. Leakage, broken

parts, hard operation and other major defects should be corrected by a repair crew as soon as possible after the defect has

been reported. If repairs are to be performed in the field, the repair crew should take a full complement of spare parts to the job

site. Provisions should be made to isolate the defective valve from water pressure and relieve internal trapped pressure prior to

performing any corrective maintenance. Disassembly of the valve should be accomplished in accordance with the procedure

supplied in the following sections. After repairing the valve, the operating mechanism should be cycled through one complete

operating cycle. An inspection should be made with full line pressure applied to the valve in open position to detect leakage

in the areas around the seal plate, bonnet, packing gland and body-end connections. A record should be made to indicate

that the valve has been repaired and is in working condition. Any marking that the valve is inoperable should be removed. In

addition, fire department and other appropriate municipal departments should be informed of satisfactory repair of the valve.

7.1 NRS VALVE REPAIRS

7.1.1 WRENCH NUT REPAIR

WARNING

Although some of the following procedures can be performed

under full working line pressure, it is recommended that any

partial disassembly or maintenance will be performed with

the water main supply line shut off and after bleeding off the

pressure!

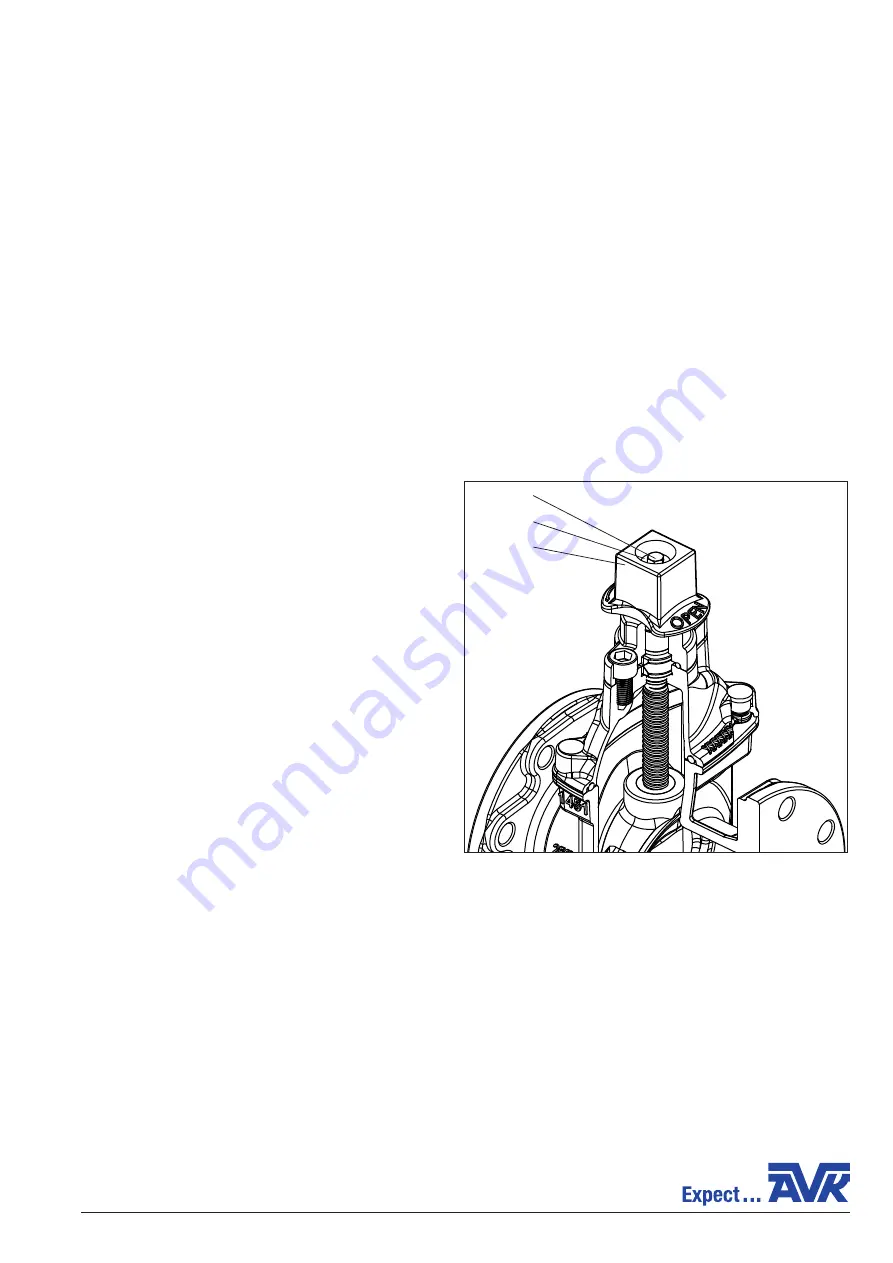

1. Remove the wrench nut bolt (F220) and wrench nut

washer (F221) using a 1/2” (13mm) wrench for DN65-100

valve sizes, and an 11/16” (17mm) wrench for DN150-200

valve sizes. Remove the wrench nut (F225) and replace

with a new one (Fig. 2A).

2. Replace the wrench nut bolt (F220) and wrench nut

washer (F221) using a 1/2” (13mm) wrench for DN65-100

valve sizes, and an 11/16” (17mm) wrench for DN150-200

valve sizes.

page 7

REPAIR PROCEDURES

In most instances, in order to keep system down time to a minimum, complete valve assembly replacement is

implemented. This also may be preferable due to physical access restrictions in the area of the valve in question. If this is the

case, as in all installation/maintenance and inspection procedures, follow all local installation and safety practices as directed

by the National Fire Protection Association, (NFPA #25 latest) and any other authorities having jurisdiction.

If system down time is not an issue, the following procedures provide repair instructions for minor issues. Leakage,

broken parts, hard operation, and other major defects should be corrected by a repair crew as soon as possible after the defect

has been reported. If repairs are to be performed in the field, the repair crews should take a full complement of spare parts to

the job site. Provisions should be made to isolate the defective valve from water pressure and relieve internal trapped pressure

prior to performing any corrective maintenance. Disassembly of the valve should be accomplished in accordance with the

procedure supplied in the following sections. After repairing the valve, the operating mechanism should be cycled through one

complete operating cycle. With full line pressure applied to the valve in the open position, an inspection should be made to

detect leakage in the areas around the seal plate, bonnet, packing gland, and body-end connections. A record should be made

to indicate that the valve has been repaired and is in working condition. Any marking that the valve is inoperable should be

removed. In addition, fire department and other appropriate municipal departments should be informed of satisfactory repair

of the valve.

NRS VALVE REPAIRS:

WRENCH NUT REPAIR:

WARNING:

Although some of the following procedures can be

performed under full working line pressure, it is recommended

that any partial disassembly or maintenance be perform with the

Water Main Supply Line shut off and pressure bled!

1. Remove the Wrench Nut Bolt (F220) and Wrench Nut Washer

(F221) using a 1/2”, (13mm) wrench, for 2 1/2” to 4” valve

sizes, and 11/16”, (17mm) wrench for 6” to 8” valve sizes.

Remove the Wrench Nut (F225), and replace with a new one.

(See Fig.3A)

2. Replace the Wrench Nut Bolt (F220) and Wrench Nut Washer

(F221) using a 1/2”, (13mm) wrench, for 2 1/2” to 4” valve

sizes, and 11/16”, (17mm) wrench for 6” to 8” valve sizes.

Fig. 3A

F220

F221

F225

Fig. 2