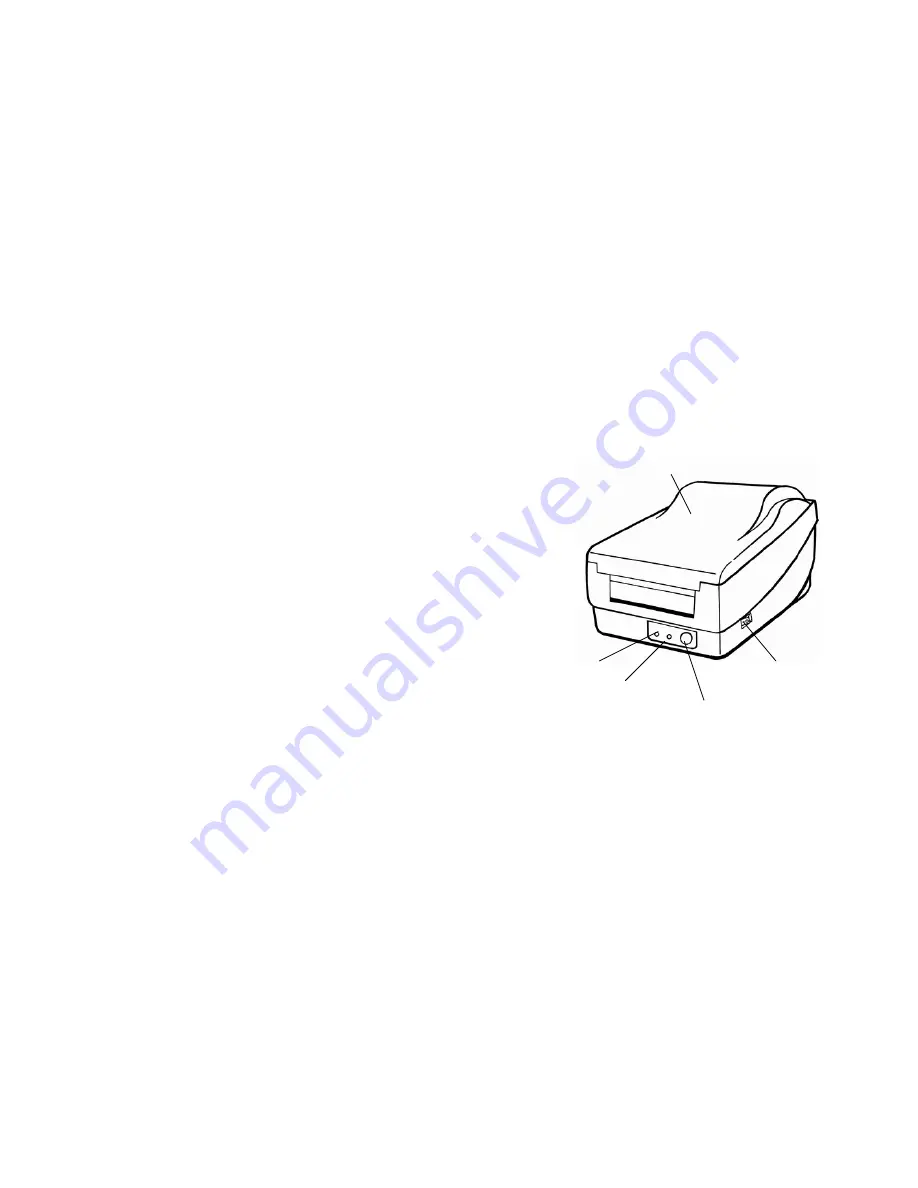

Operator Controls

Power Switch

Controls printer power

On-normal operation

Off-the power should be turned off before connect or disconnect

the communication cables and power cables

Feed Button

Advance the label media to first printing position

Press-to advance a label

Press-takes the printer out of a "pause" condition

Press-back feed the label to correct label installation, in case that

label is not properly installed. (for OS-202 Peel-Off mode only)

Keep pressing while turning on the power- to print out a

configuration profile

Ready Indicator

Show the printers status

Green-printer is ready to operate

Blinking-printer is paused

Power indicator

Shows the power and error status

Off-printer power off

Green-printer power on

Blinking-error occurs

26

Power Indicator

Ready Indicator

Power Switch

Top Cover

Feed Button

25