User Manual

www.AvantcoEquipment.com 5

Blade Sharpening

1. This operation should be undertaken if the cutting blade becomes dull. It should be noted that the blade is made

from hardened material and under normal use should only need sharpening once a year.

2. Unplug the unit.

3. Ensure that the slice thickness knob is in the ‘0’ position.

4. CAREFULLY clean the part of the blade to be sharpened.

5. Unlock the sharpening device using the safety locking screw. Lift up the sharpening assembly and rotate it 180° so

that both grinding wheels are in the correct position. Lower the sharpening device and lock in position.

6. Plug in the machine and switch on.

7. Using the button at the rear of the sharpening unit, push the stone against the rotating blade for approximately

30 seconds.

8. After sharpening, it is important to remove the grinding wheel from the blade by letting go of the push button on the

front of the sharpening device. Run the slicer for 2-3 seconds after letting go of this button.

9. Return the sharpening device to its original position by unlocking the safety screw and rotating by 180°.

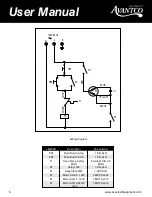

Electrical Connection Information

Electrical Connection Information

Model

Description

Volts /HZ

HP

Watts

Plug Type

SL309

Avantco Slicer 9”

120 / 60

1/4 HP

200 W

NEMA 5-15P

SL310

Avantco Slicer 10”

120 / 60

1/4 HP

320 W

NEMA 5-15P

SL312

Avantco Slicer 12”

120 / 60

1/3 HP

420 W

NEMA 5-15P

SL512

Avantco Slicer 12” Medium Duty

120 / 60

1/2 HP

450 W

NEMA 5-15P

Technical Specification

Model

Blade Dia.

Blade Rotation

Speed

Cut Thickness

Cut Capacity

Net Weight

Operating Noise

Level

SL309

9”

532 rpm

0 - 0.4”

6.3 x 7.5”

29lbs

60-67 dB(A)

SL310

10”

465 rpm

0 - 0.4”

6.7 x 7.5”

32lbs

SL512

12”

300 rpm

0 - 0.6”

9.3”x 6”

64lbs

SL312

12”

428 rpm

0 - 0.6”

9.4x 6”

54lbs