Revised 4/3/00 • M220nx

6

© 2000 Automated Logic Corporation

• 0 to 5VDC: The output impedance of a 0

to 5VDC source must not exceed

10kohms. The input impedance of the

M220nx is approximately 1Mohm.

• 0 to 20mA: The input resistance on the

“A” input is 250 Ohms. The “B” terminal

supplies a voltage source to power the

4-20mA transducer. The “B” terminal is

capable of supplying 18 to 24VDC, but

the total current of both “B” terminals

must not exceed 40mA. If the voltage

measured from the “B” terminal to Gnd

is less than 18VDC, you need to use an

additional external power supply.

• Dry Contact: A 5VDC wetting voltage is

used to detect contact position. This

results in a 0.5mA maximum sense

current when the contacts are closed.

The M220nx accumulates up to ten input

pulses per second.

1. Be sure the M220nx’s power is off before

wiring any inputs or outputs.

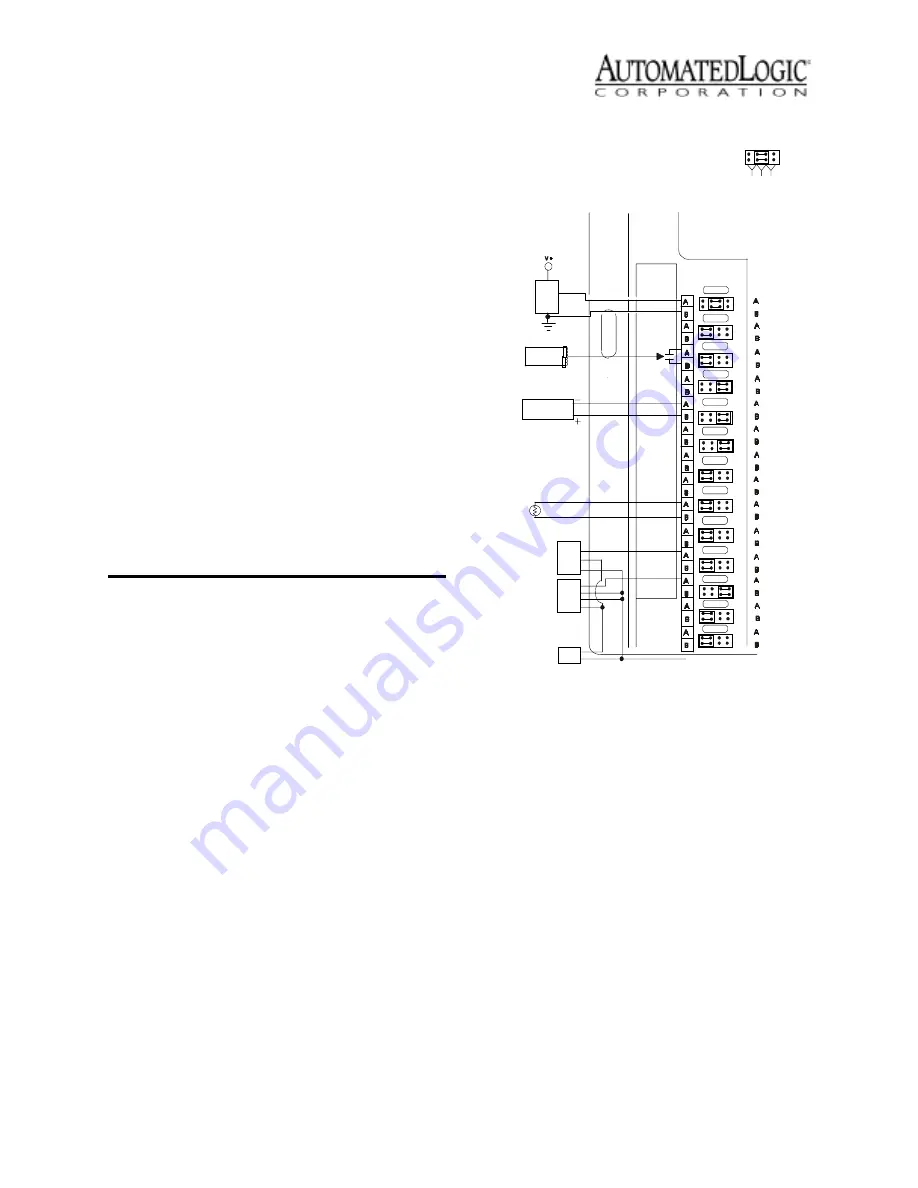

2. Connect the input wiring to the screw

terminals on the module as shown in

Figure 4.

NOTE

If a 4-20 mA sensor uses an

external 24VAC power supply, connect

one leg of the 24VAC supply to the module

ground.

3. Set the configuration jumper for each

input to indicate the type of input used.

Make sure the jumper is positioned

correctly, and be sure to grip the jumper

by the sides only. See Figure 5 on page 7.

4. For each input, enter the channel number,

offset, and gain on the Function Block’s

Parameter page in SuperVision. Valid

channel numbers are listed in “Channel

Numbers” on page 7.

5. To verify each input’s operation, have

each sensor create a known value and

Table 2. Input wiring restrictions

Input

Maximum

Length

Minimum

Gauge

Shielding

0 to 5VDC

50 feet

15 meters

24AWG

shielded and

grounded to

module’s

“

B

”

or Gnd

terminal

Thermistor

Dry contact

50 feet

15 meters

24AWG

shielded and

grounded to

module’s

“

B

”

or Gnd

terminal

0 to 20mA

150 feet

46 meters

20AWG

unshielded

Figure 4. Input Wiring

PW R

PW R

PW R

OUT

OUT

GND

GND

GND

0-5VDC

DRY

CONTACT

PASSIVE

TRANSDUCER

4-20mA

12V or 24V

LOOP INPUT

THERMISTOR

3 WIRE

4-20mA

ISOLATED AC

or DC POWER

SUPPLY

4 WIRE

4-20mA

OUT +

OUT -

OUT +

OUT -

TO MODULE GND

Universal Input

Mode Select

0-

5

V

D

C

0

-20mA

Th

e

rm

ist

o

r

Dr

y

C

onta

c

t

Inputs

5V Max, 20mA Max