Revised 11/19/99 • BACview

2

Hardware Guide

4

© 1999 Automated Logic Corporation

3. Use the rear mounting plate as a template

to drill four mounting holes onto a panel

directly above the module the BACview

2

will communicate with.

4. Feed the ribbon cable through the ribbon

hole on the rear mounting plate.

5. Pull the ribbon cable to the side and

mount the rear mounting plate onto the

panel using the four mounting holes

shown in Figure 2 on page 3. Be sure not

to bend or pinch the ribbon cable beneath

the rear mounting plate.

6. Connect the ribbon cable to the face of the

BACview

2

.

7. Reattach the BACview

2

to the rear

mounting plate.

8. Connect the ribbon cable to the module’s

Auxiliary Device port (see Figure 3).

Type II Mounting

The BACview

2

can be mounted on the door of

a panel box. With this type of mounting the

ribbon cable is fed through the door and

connected to the module (see Figure 4 on

page 5).

1. Remove the rear mounting plate screws

(see Figure 2 on page 3 for location) from

the BACview

2

.

2. Remove the rear mounting plate from the

BACview

2

.

3. Use the rear mounting plate as a template

to drill four mounting holes through the

door of a panel box.

4. Use the rear mounting plate as a template

to cut a hole for the ribbon cable through

the door of a panel box.

5. Feed the ribbon cable through the ribbon

hole on the rear mounting plate and the

panel door.

6. Mount the rear mounting plate onto the

panel using the four mounting holes

shown in Figure 2 on page 3. Be sure not

to bend or pinch the ribbon cable beneath

the rear mounting plate.

7. Connect the ribbon cable to the face of the

BACview

2

.

8. Reattach the BACview

2

to the rear

mounting plate.

9. Connect the ribbon cable to the module’s

Auxiliary Device port mounted inside the

panel box (see Figure 4 on page 5).

BACview

2

Wiring

CAUTION

The BACview

2

is a Class 2 device

(less than 30 VAC, 100VA max). Take

appropriate isolation measures when

mounting a BACview

2

in a control panel

where Class 1 devices or wiring are present.

1. Turn off the power to the module the

BACview

2

will communicate with.

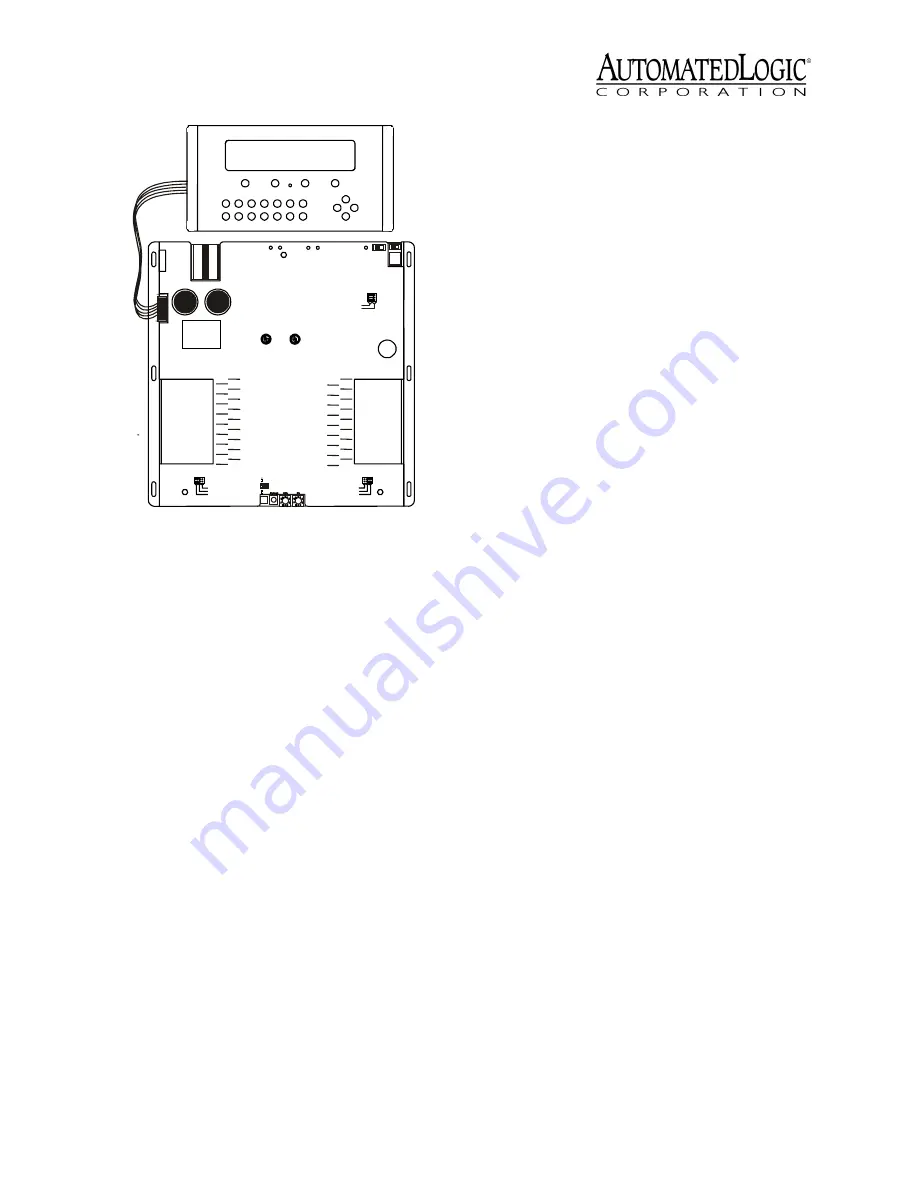

Figure 3. Type I Mounting

T yp e: 0 32 0

Ca t. #

MODULE

I/O

E xp a n s io n

A - I n p u t S i g n a l

B - G n d / L o o p P o w e r

I/O

E xp a n s io n

A

B

A

B

A

B

A

B

A

B

A

B

A

B

A

B

IN 1

IN 2

IN 3

IN 4

IN 5

IN 6

IN 7

IN 8

IN 9

IN 10

IN 11

IN 12

IN 13

IN 14

IN 15

IN 16

IN 24

IN 23

IN 22

IN 21

IN 20

IN 19

IN 18

IN 17

B

A

B

A

B

A

B

A

B

A

B

A

B

A

B

A

IN 3 2

IN 3 1

IN 3 0

IN 2 9

IN 2 8

IN 2 7

IN 2 6

IN 2 5

B

A

B

A

B

A

B

A

B

A

B

A

B

A

B

A

0 - 2 0 m A

0 - 5 V d c

T h e r m i s t o r

/

d r y c o n t a c t

O n

O f f

G n d

2 4 V a c

C l a s s 2

2 4 V a c , 5 0 - 6 0 H z

3 5 V A , 1 . 5 A

U s e C o p p e r

C o n d u c t o r s O n l y

A

B

A

B

A

B

A

B

A

B

A

B

A

B

A

B

R un

Er ro r

Control Module

P o w er

A c c es s

P or t

R x

N e t

+

N e t

-

O p t i o n a l

S h i e l d

T x

A uxil ar y

D e vic e

P o rt

C M n e t

U n i v e r s a l I n p u t

1 - 1 6

M o d e S e l e c t

0 - 2 0 m A

0 - 5 V d c

T h e r m i s t o r

/

d r y c o n ta c t

U n i v e r s a l In p u t

1 7 - 3 2

M o d e S e l e c t

M od ule

A ddr es s

A rc 15 6

R

L IST E D

8 8 FO

O pe n En erg y

Ma na ge m ent Equ i pmen t

R

LI S TE D

8 8F O

C

C M n e t M od e

U s e S i n g l e C l a s s 2

S o u r c e O n l y

960 0/ 38.4 k