11

ECOTIG-160

OPERATION

When ARC welding, your amperage/current should be determined by the

electrode size, the knob adjusts this setting.

Before welding, ensure that you have your welding mask on and set to the arc

function if applicable.

The electrode should be around 1.5mm to 3mm away from the workpiece until

the arc is made, once the arc has started, move the rod in a steady motion in

one direction across where you would like your weld. Once you have finished

your weld, pull the rod away from the workpiece and remove any excess weld

spatter with the wire brush that is supplied with your welder and a hammer.

Before starting a new weld, inspect the rod used to make sure that the tip is

concentric. If not, you can re-sharpen the tip using a grinding wheel or change

the rod completely.

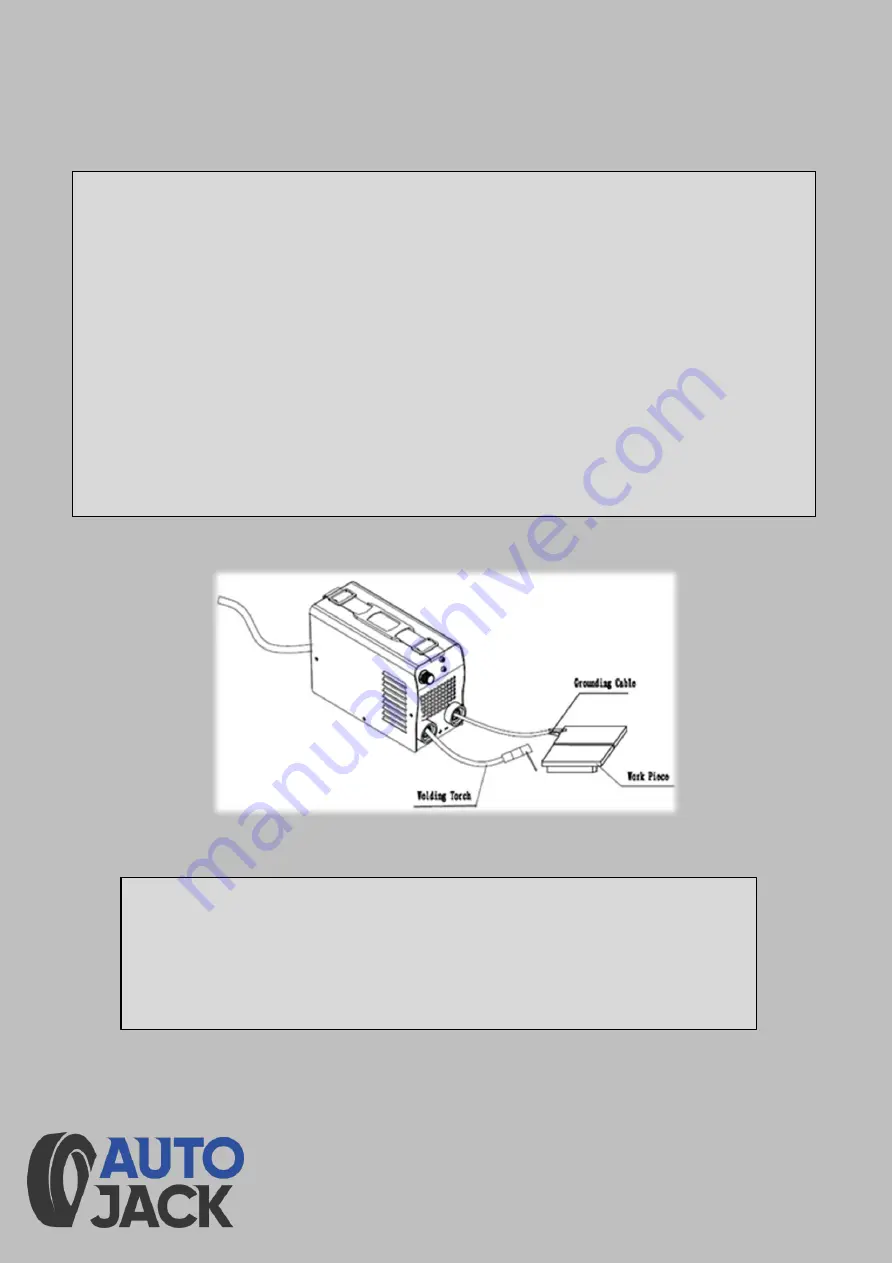

The image below shows how this welder should be set-up for arc welding.

When the welder has been used for a prolonged period of time, the

overheat light may illuminate.

If this happens, please stop using the machine until it goes out.

Turning the machine off when in this state can cause damage to an

internal PCB.