2920 1371 00

5

Instruction book

Oil-free Air Division

is warmed up by the incoming air to approx. 10°C (18°F)

below the incoming air temperature. Reheating the dried air

reduces its relative humidity, so that condensation in the air

net cannot occur unless the air is cooled to below the pressure

dewpoint temperature indicated by gauge (1).

1.3 Refrigeration circuit (Fig. 2)

Compressor (M1) delivers hot, high-pressure refrigerant gas,

which flows, via the coil(s) of liquid separator(s) (7), through

condenser (9) where most of the refrigerant condenses. On

air-cooled condensers, a fan control switch (S3) stops and starts

the fan motor (M2) at falling or rising condenser pressure. On

water-cooled condensers, an automatic valve (3-Fig. 5a)

regulates the cooling water flow, thus controlling the

temperature, which is directly dependent on the pressure. The

cooled refrigerant then collects in receiver (10).

The liquid leaves the receiver (10) via its syphon outlet and

flows through liquid refrigerant dryer (12), via refrigerant/

refrigerant heat exchanger (17) and sight-glass (8), to expansion

valve (13) where it expands to evaporating pressure.

In expansion valve (13) some of the expanding liquid refrigerant

evaporates, for which the required heat is withdrawn from the

refrigerant itself.

The refrigerant enters the heat exchanger/evaporator (15) where

it withdraws heat from the compressed air by further

evaporation. Dependent on the compressed air load, all, or

almost all, refrigerant evaporates at constant pressure and

temperature. The vapour refrigerant leaving evaporator (15)

flows into liquid separator(s) (7) via refrigerant/refrigerant heat

exchanger (17). The liquid separator prevents any droplets

from entering compressor (M1) because warm refrigerant,

leaving the compressor, flows through the coil(s) of the liquid

separator(s) and evaporates the surrounding liquid. From liquid

separator(s) (7) the refrigerant gas is sucked in by the

compressor.

The dryers are provided with a sight-glass (8). The sight-glass

allows to check the refrigerant flow in the line. During normal

operation, the liquid flow must be clear. In general, vapour

bubbles indicate a shortage of refrigerant. Note that fluctuations

in the load may cause bubbles to pass in the flow for a short

time. The center of the glass is provided with a moisture

indicator which is green when the liquid refrigerant is free of

moisture. It will turn into yellow when the refrigerant contains

moisture, indicating that the liquid dryer needs to be replaced.

1.4 Automatic regulation system

(Fig. 2)

Expansion valve (13) maintains the evaporating temperature

between 1 and -1°C (34 and 30°F); these are the approximate

limit temperatures at zero and maximum air load respectively.

At partial or no load, the excess cooling capacity is transferred

in liquid separator(s) (7). The condenser pressure must be kept

as constant as possible to obtain stable operation of expansion

valve (13). Therefore, on air-cooled dryers, fan control switch

(S3) stops and starts cooling fan (M2). On water-cooled dryers,

the temperature is controlled by an automatic regulating valve

on the water circuit. The switch or regulating valve ensures

proper operation at low air load and/or low ambient temperature.

1.5 Electrical system

These dryers are three-phase units.

The refrigerant compressors are equipped with a crankcase

heater. When voltage is supplied, the heater is energized. It

keeps the oil in the crankcase warm to prevent condensing of

refrigerant in the compressor housing, which could result in

serious damage of the compressor at restart (liquid knock).

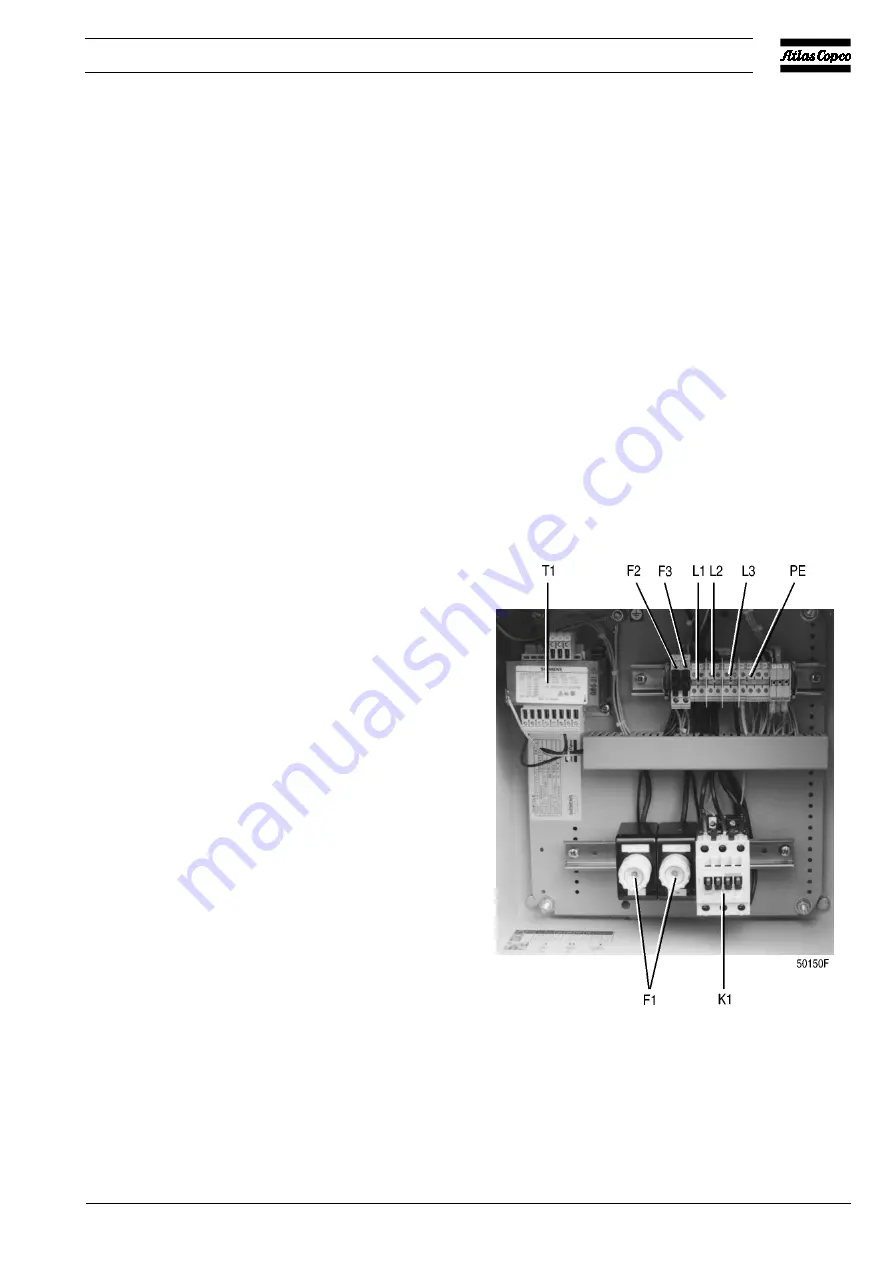

F1.

Fuses, fan motor

F2/F3. Fuse, secondary side (24 V) of transformer

K1.

Motor contactor, refrigerant compressor

L1/3.

Terminal, mains

PE.

Earth terminal

T1.

Transformer

Fig. 3. Electric cubicle (typical example)

Summary of Contents for FD1200

Page 11: ...2920 1371 00 11 Instruction book Oil free Air Division Fig 6b Dimension drawing of FD560 W...

Page 12: ...2920 1371 00 12 Oil free Air Division Instruction book Fig 6c Dimension drawing of FD700...

Page 13: ...2920 1371 00 13 Instruction book Oil free Air Division Fig 6d Dimension drawing of FD700 W...

Page 16: ...2920 1371 00 16 Oil free Air Division Instruction book Fig 6g Dimension drawing of FD1600 W...