40

The warranty on Corbin Russwin products becomes void if the product is modified in any way, regardless of whether the modifications causes or contributes to any alleged defect. If a

Corbin Russwin product is modified it may no longer meet industry certification and quality control standards applicable to the original product and is no longer a genuine Corbin Russwin product.

Copyright © 1999-2018, ASSA ABLOY Access and Egress Hardware Group, Inc. All rights reserved. Reproduction in whole or in part without the express written permission of ASSA ABLOY Access

and Egress Hardware Group, Inc. is prohibited. Patent pending and/or patent www.assaabloydss.com/patents.

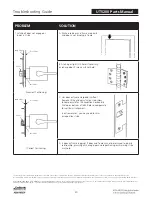

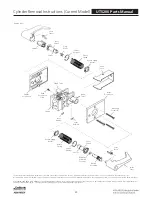

Service Procedures

UT5200 Parts Manual

6. Before proceeding, make mental note of chassis orientation

relative to parts already laid out. Use ribbed wall as

reference point and remember whether it faced left or right

All functions except UT5210 and UT5282 have a spindle

which passes through chassis tube from one side, continues

through various hubs and spacers in center of chassis and

continues outward through opposite chassis tube. Parts vary

by function and so does direction of spindle removal.

Carefully tilt chassis to look into each end of tube and

determine which end of spindle is smaller. Hold chassis

so small end of spindle points upward. If spindle falls out

bottom tube at this to point, lay it out with other parts on

proper side of work space and proceed to step7. Otherwise,

look for small pin through hole in end of spindle.

Push spindle up from bottom until small pin can be removed

through hole in chassis tube. Caution! Cover top end of

tube during this process. Some functions have parts which

spring off spindle when pin is removed. Spindle should now

drop out. If not, gently rotate it until it falls out. Lay spindle

and all other parts out in order on proper side(s) of work

space.

7. Observe order and orientation of hubs and spacers inside

chassis. Consult exploded view page for reference. Depress

main latch to allow hubs to fall out. Again, lay them out

carefully in center of work space from left to right as

originally installed. Disassembly is now complete.

8. Turn chassis over so opposite tube points up. Depress main

latch and reload hubs in same order as removed. Refer to

appropriate exploded view page if parts get mixed. Caution:

if any hub has a rectangular or “double-D” hole, its

orientation is critical. Diagonal flats of hole must face holes

in latch tube.

9. Install small end of spindle from bottom, passing through all

hubs. If spindle has flat sides, verify that hole in spindle faces

holes in frame tube. If not, Step 8 was incorrect.

10. Supporting spindle with finger in bottom tube, reinstall

other parts (

depending on function

) over top end of

spindle. In the case of some spring loaded assemblies, use

small screwdriver to depress assembly into the chassis far

enough to clear hole in end of spindle. Insert retainer pin

through frame tube hole and install into spindle.

Before proceeding, check orientation of all parts in chassis

against exploded view page. For comparison, all pages

illustrate left hand reverse bevel assembly.

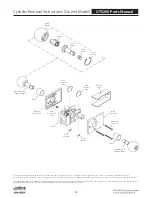

11. Remembering original left to right orientation of chassis

on work space, turn chassis upside down so knobs and

escutcheons are ready to install on opposite sides from

original orientation. Note: Opposite escutcheon now

becomes fixed (

always attached to ribbed wall of chassis

).

Only small screw and washer must switch sides at this

point. These must enter from other side of chassis for

reassembly.

Observe sides of chassis and locate side with three vertical

ribs. Install trim on this side first.

12. Place circular wire retainer around frame tube, but do not

push all the way into position.

13. Put sleeve into back of knob and place that assembly

through hole in escutcheon. Slide knob into frame tube

as far as it will go. If this knob has cylinder, be sure top of

keyway points toward latch (

edge of door

). Groove around

the knob shank should now be positioned under the

retainer slot in the frame tube.

14. Install crescent knob retainer and move retainer ring into

place to secure crescent retainer.

15. Install fixed escutcheon screw and washer with screwdriver

through hole in opposite wall of chassis. (Tip: Use

needlenose pliers to position screw inside chassis for

screwdriver tip and point lockset upward to start screw into

threads.)

16. Repeat steps 10, 11, and 12 for remaining side.

17. For all functions except UT5282 (

store door

), proceed to

step 18. For UT5282, small retainer removed in step 2 must

be reinstalled. This can be very difficult without Waldes ring

applicator.

18. Test operation of all keys, buttons and knobs.

Install chassis cover and throughbolts.

Changing Hand of Lockset (cont'd)

Knob Version