BUILDING CONNECTIONS THAT LAST

5

GROOVER DESCRIPTION

*“

RIDGID” is a registered trade mark of Emerson Electric Company.

Note: See Section XI for further details of parts for the 3006 and 3006C Roll Groover.

A. 3

006 STANDARD EQUIPMENT

Roll Groover complete with Adjustable Support Leg Assembly and

roller sets for grooving 2"-6" and 8"-12" steel pipe, Steel/CTS Dual

Guide Roll Assembly, hydraulic pump with pressure gauge, and two

depth adjustment gauges. This unit is designed for direct attachment

to your Ridgid

®

300 Power Drive. Complete with comprehensive setup,

operating and troubleshooting instructions.

Shipped in a reusable wooden storage crate.

Approximate shipping weight: 225 pounds.

Required Ridgid® 300 Power Drive not included.

B. 3006 OPTIONAL EQUIPMENT

CTS COPPER SYSTEM:

• 2"- 8" CTS Copper System Grooving Rolls, 2"- 4" CTS Depth

Gauge, and 5"- 8" CTS Depth Gauge.

A. 3

006C STANDARD EQUIPMENT

Roll Groover complete with Adjustable Support Leg Assembly and

CTS Copper System roller set for grooving 2"-6" copper tube, CTS

Guide Roll Assembly, hydraulic pump with pressure gauge, and 2"-6"

Universal Diameter Gauge. This unit is designed for direct attachment

to your Ridgid

®

300 Power Drive. Complete with comprehensive setup,

operating and troubleshooting instructions.

Shipped in a reusable wooden storage crate.

Approximate shipping weight: 215 pounds.

Required Ridgid

®

300 Power drive not included.

B. 3006C OPTIONAL EQUIPMENT

STEEL OPTION:

• Consisting of 2"-6" and 8"-12" roll sets, Steel/CTS Dual

Guide Roll Assembly, and two depth adjustment gauges

1. All wall thicknesses shown are the maximum wall thicknesses for the indicated pipe material.

2. Minimum wall thickness for each pipe material and size is:

Steel: 2"-12" Schedule 10

Stainless Steel: 2"- 12" Schedule 10S, 40S

Copper:

2"- 21/2" - Type M

3"- 8" - Type DWV

3. Please contact an Anvil Representative for information on grooving alternate materials and wall thickness.

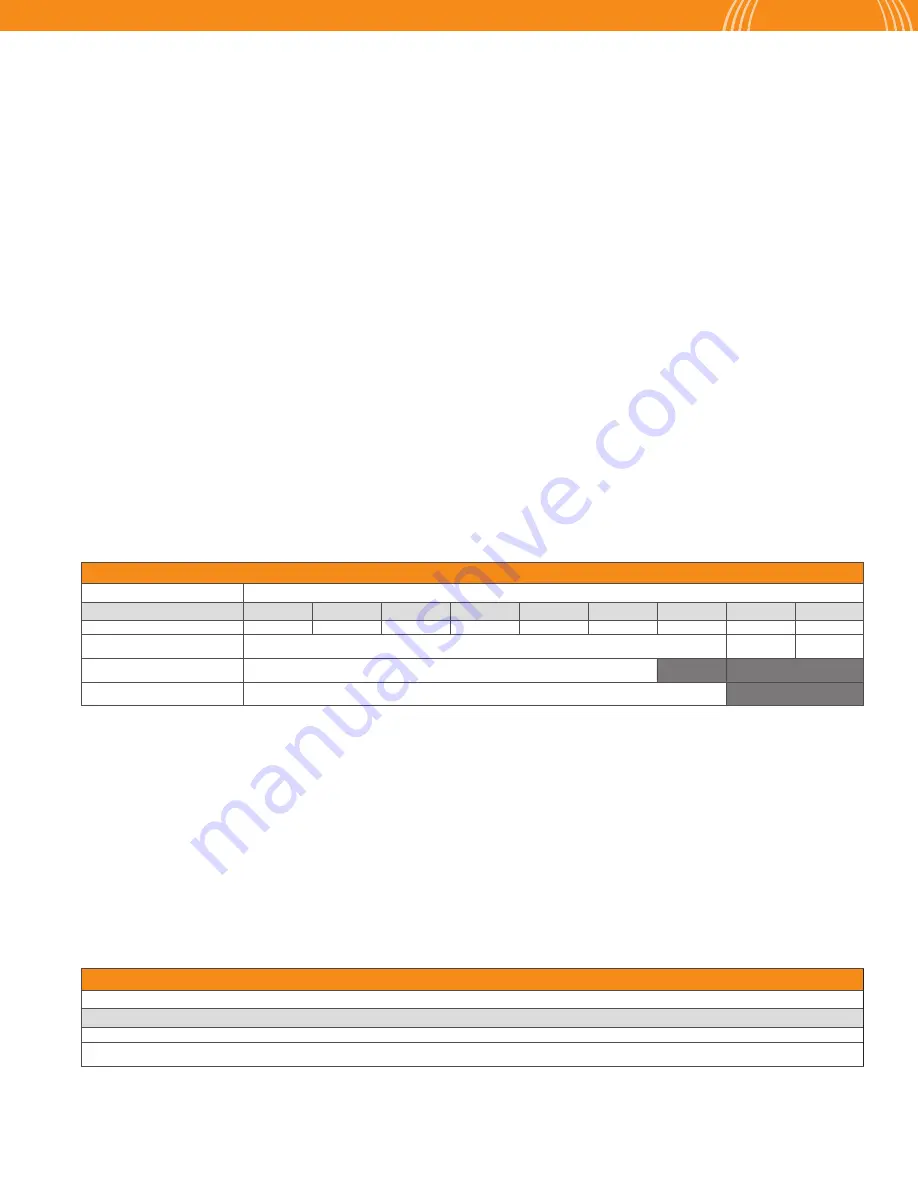

GROOVER CAPABILITY

Pipe Material

Pipe Size/Wall Thickness (Schedule)

1,2

In.

2

2

1

⁄

2

3

4

5

6

8

10

12

DN(mm)

50

65

80

100

125

250

200

250

300

Steel

Schedule 10, 40

0.188

"

0.219

"

Stainless Steel

Schedule 10S, 40S

Copper

K, L, M & DWV

MODEL 3006/3006C STEEL PIPE GROOVING TIMES (MINUTES: SECONDS)

Pipe Size (In./DN(mm))/Max Steel Pipe Wall Thickness

2

2

1

⁄

2

3

4

5

6

8

10

12

50

65

80

100

125

150

200

250

300

0:20

0:20

0:25

0:30

1:00

1:20

1:35

1:50

2:20

C. 3006/

3006C GROOVER CAPABILITY

D. GROOVING TIMES

This chart shows approximate grooving times with the groover set-up for the proper size and groove diameter and the pipe properly positioned on the

groover. The times shown are average times from the start of rotation of the pipe in the grooving rolls to completed groove.