installation &

oper ating instructions

E.2 Series high efficiency

circulator

7

9

Install the new stationary seal seat into the faceplate by

firmly pressing it down until it bottoms. The disk should

be clean. If needed, wipe it with alcohol and a soft lint

free cloth.

10

Replace the faceplate on the motor housing extension,

being careful to avoid shaft contact. This may need to be

gently tapped down until tight to the housing. Be sure to

check that the stainless steel plate is flush to the extender

plate face.

11

Install the special

installation tool

(item

#180212-095

) on

the top of the shaft making sure it is tight to the flat base of

the impeller to protect the seal from sharp edges during

seal installation.

12

Apply a liberal amount of non-petroleum based lubricant

on the outside of the special plastic

installation tool.

13

Wipe any excess lubricant off of the stationary silicon

carbide seal face with a lint free cloth and alcohol to ensure

the surface is clean.

14

Install the new rotating seal element and spring assembly

by gently pushing it (graphite ring first) over the

installa-

tion tool

and onto the shaft until the graphite ring presses

tightly against the stationary seal seat. The seal spring may

be compressed slightly.

15

Remove the

installation tool

from the shaft.

16

Install the impeller keeping the inlet end up. Make sure to

align the flats to the shaft flats and push the impeller down

tightly to the seal.

17

Place

2-3

drops of medium strength thread locker liquid on

the nut threads.

18

Install the special left hand thread nut on the motor shaft.

While holding the motor rotor in place as in step

3

, thread

the impeller nut on to the shaft in a counter-clockwise

direction and tighten the nut to approximately

6

ft-lbs.

19

If the impeller will not spin freely contact Armstrong

Technical Support at

1-416-755-2291

or email

20

Ensure the gasket is properly seated in the pump casing

(volute) gasket groove. Holding the motor body, insert

the impeller straight into the volute. Verify the gasket was

not dislodged during insertion, and is still seated properly.

Hold the motor body steady while fastening the four bolts

that attach the motor to the pump casing (volute). Tighten

evenly and diagonally. There should be a small, even gap

of about

0.02

" (

0.5

mm) between the motor flange and the

pump casing (volute).

21

Follow the

start up

instructions (File no.

10.84

)

and check for leaks.

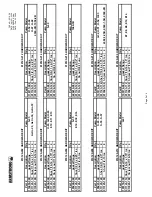

casing

impeller nut

(left hand thread)

mechanical seal

impeller

seal seat and l-cup

casing gasket

faceplate

housing extender

motor assembly

motor

bolt (4)

seal installation tool