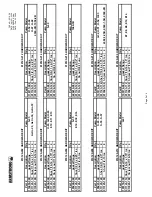

FILE NO.: 6010.28

DATE: April 21, 2009

SUPERSEDES: New

DATE: Feb. 23, 2006

Circulator Flange Dimensions

Individual flanges

Armstrong

Bell & Gossett

Dimensions

Cast iron

Bronze

Cast iron

Bronze

A

B

C

D

Diagram

104300-011 104300-041

P03300

P06660 1 ¼” 3

7/16"

4 ¾”

½”

1

104301-011 104301-041

P03410

P06690 1 ½” 3

7/16"

4 ¾”

½”

1

105188-011 105188-041

F74000

F74800

3"

5

1/16"

6"

9/16"

2

105189-011 105189-041

P03560

P06750 2 ½” 5

1/16"

6"

9/16"

2

105210-011 105210-041

---

---

2"

3 ¾”

4

7/8" 9/16"

2

106073-011 106073-041

P01500

P06620

1"

3

7/16"

4 ¾”

½”

1

106074-011 106074-041

---

---

2"

3

5/32"

5

1/8"

5/8"

2

116009-011 116009-041

P03430

P03450 1 ½” 3

5/32"

4 ¼”

½”

1

116011-011 116011-041

P03250

P06640 1 ¼” 3

5/32"

4 ¼”

½”

1

116012-011 116012-041

P01510

---

1"

3

5/32"

4 ¼”

½”

1

116013-011 116013-041

P00740

---

¾”

3

5/32"

4 ¼”

½”

1

133615-010 106466-041

A24600

---

3"

6"

7 ½”

¾”

2

Page 4 of 4

Page 4 of 4